Automatic Solder Paste Mixer 500g-1000g ZB500S for repair PCB

Product Detail

Product Tags

Automatic Solder Paste Mixer 500g-1000g ZB500S for repair PCB

Overview

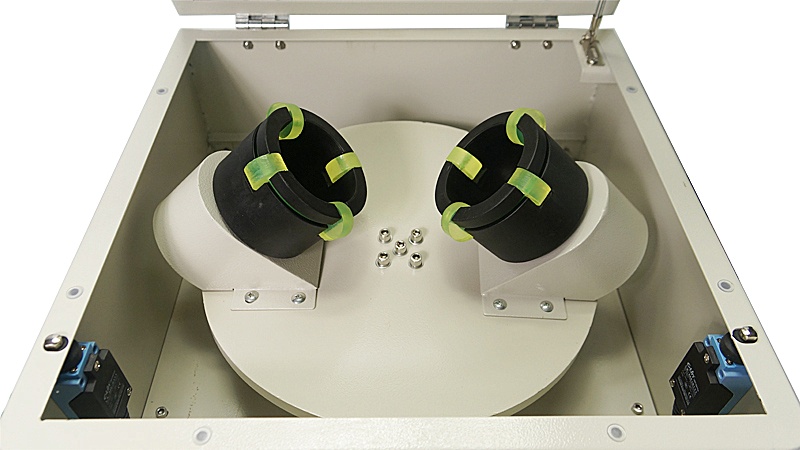

ZB500S Automatic Solder Cream Mixer makes solder cream move downward constantly through

centrifugal force generated by revolution and cooperation with energy from rotation at 45 degree

angle of axis of revolution. Solder cream located in the tank bottom makes upward movement from

the surrounding, which forms a tornado-funnel shaped stirring action, and it can stir, soften and

defoam the solder cream with appropriate viscosity. Solder cream has good wettability, even

diffusivity, excellent printing effect after mixing, which achieves the best welding performance when

reflowing soldering. Its characteristics are as follows:

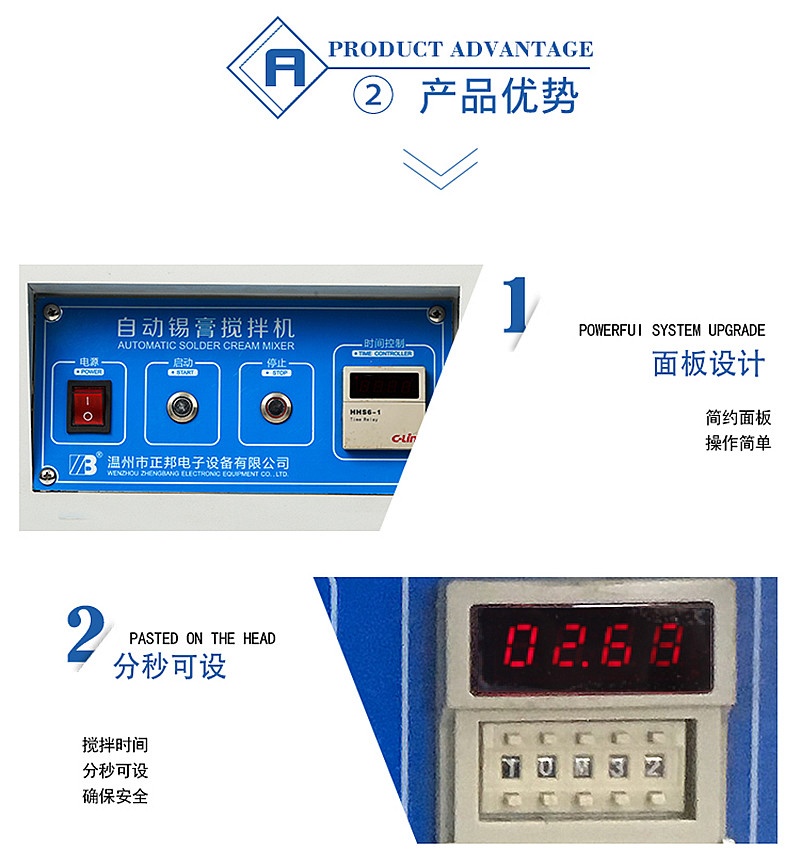

·There is special control circuit, adjustable mixing time and easy operation.

·Solder cream is placed by 45 degrees and rotates along axis direction and solder cream won’t

stick to the pot cover.

·Smooth operation, low noise, temperature return naturally and bubble remove in the process of

mixing.

·There is no need to open cover for solder cream pot and it is convenient and safe for

pick-and-place.

·There is safety device to ensure the personal safety.

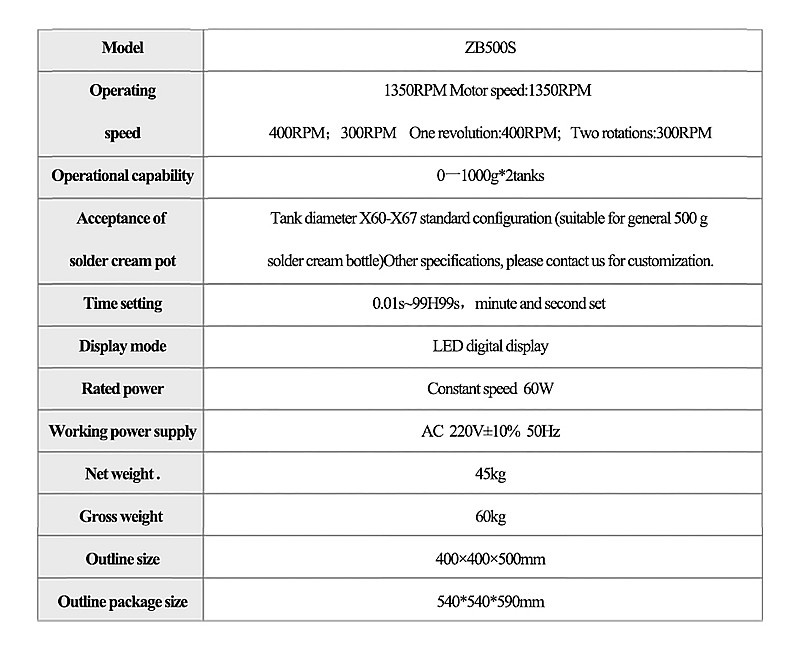

Technical parameters

|

Type |

ZB500S |

| Operating speed |

Motor speed: 1350RPM

|

|

One revolution: 400RPM; Two rotations: 300RPM |

|

|

Operational capability |

0-1000 g * 2 tanks |

|

Acceptance of solder cream pot |

Tank diameter Φ60-Φ67 standard configuration (suitable for general 500 g solder cream bottle)

Other specifications, please contact us for customization. |

|

Time setting |

0.01s~99H99s, minute and second set

|

|

Display mode |

LED digital display

|

|

Rated power |

Constant speed 60W |

|

Working power supply |

AC 220V±10% 50Hz

|

|

Boundary dimension |

400×400×500mm |

|

Machine weight |

50kg |

Attachment list

1. Adjustment belt 2 PCS

2. Rotation belt 2PCS

3. Balance weights 500g 1PCS

4. Instruction book 1PCS

5. Certificate of quality 1PCS

6. Lining 2PCS

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!