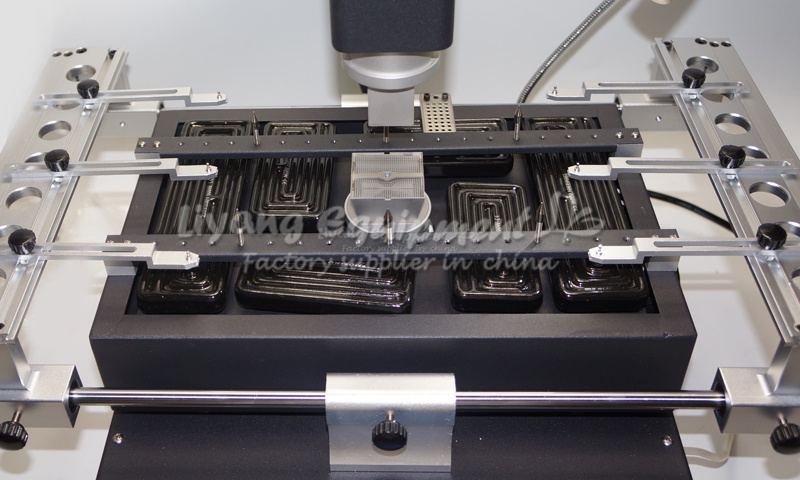

HT-R490 classic 3 zones hot air bga station original BGA rework station 220V 110V

Product Detail

Product Tags

Basic parameters of the machine:

1 Power: Single phase 220V AC 50/60HZ 4KVA

2 Total power: 4000W

The upper heating power: 800W

Bottom heating power: 800W at the bottom of infrared heating power: 2400W Standby power: ≤ 10W

3 temperature control mode: High-precision K-type thermocouple closed-loop control, with electronic temperature compensation.

4.PCB positioning mode: V-groove + Z fonts universal fixture pairs of Y-direction adjustment

5 PCB size: MIN 10mm * 10mm MAX 350mm * 400mm

6. Infrared Preheating area: 210mm * 340mm

Machine Dimensions: (or so) wide and 580mm * (before and after) long 580mm high 650mm

Machine weight: Net weight 35KG

New features:

A: the world’s most advanced “intelligent control system (Intelligent control system), referred to as” ICS ”, BGA rework desoldering more humane, more simple, more intelligent.

B: The superior fault alarm function, the following fault detection and alarm control system integration:

1: K-type thermocouple open circuit detection and fault alarm protection. So that the temperature out of control, such as temperature overshoot fault no longer occurs.

2: up and down the hot air fan fault detection and fault alarm protection. Heater burnout phenomenon as history, to maximize the protection of machinery and personal safety.

3: heater fault detection and fault alarm, the machine’s real-time status at a glance.

C: upper and lower blast volume electronic smart speed. Ask each group to different temperature curve to match the different wind speed, improve repair efficiency, enhance the repair success rate. Exempt from the tedious and repetitive traditional machine mechanical wind speed adjustment.

D: double-Y direction PCB clamping bracket to meet the larger PCB fixed.

Basic functions:

1 Precision imported raw materials (PLC. heater) precise control of BGA desoldering process.

2 The machine uses the independent control of three-zone temperature control is more accurate. The first temperature zone. Second temperature zone can be set in paragraph 8 liters (down) 8 segments constant temperature control, which can store 10 groups of temperature curve. The third zone warm-up, independent temperature control to ensure fully preheat the PCB during the soldering process,

3 Selection of imported high-precision thermocouples, precise temperature detection.

4 walk alone the temperature curve in the upper heating and bottom heating, cross-flow fan rapid cooling principle to ensure that the PCB during the soldering process, will not be deformed.

5 demolition welding and welding finished 20 seconds ahead of progressive alarm with a vacuum suction pen, convenient desoldering suction trips to the BGA

6 PCB positioning using a V-shaped slot, flexible and convenient removable universal fixture, PCB protection.

For large thermal capacity of PCB and other high temperature requirements of lead-free soldering and so can easily handle.

Hot air Tsui 360 degree rotation, easy to replace. With a variety of size of hot air nozzle, special requirements can be customized for notebook computer motherboard, desktop computers, motherboards, and other large-scale circuit board repair, and cell phone motherboard micro maintenance of the chip

Thanks for your order!

Questions, issues or concerns? I'd love to help you!