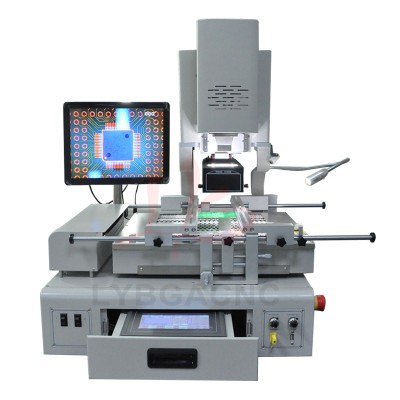

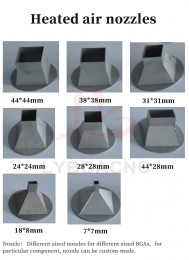

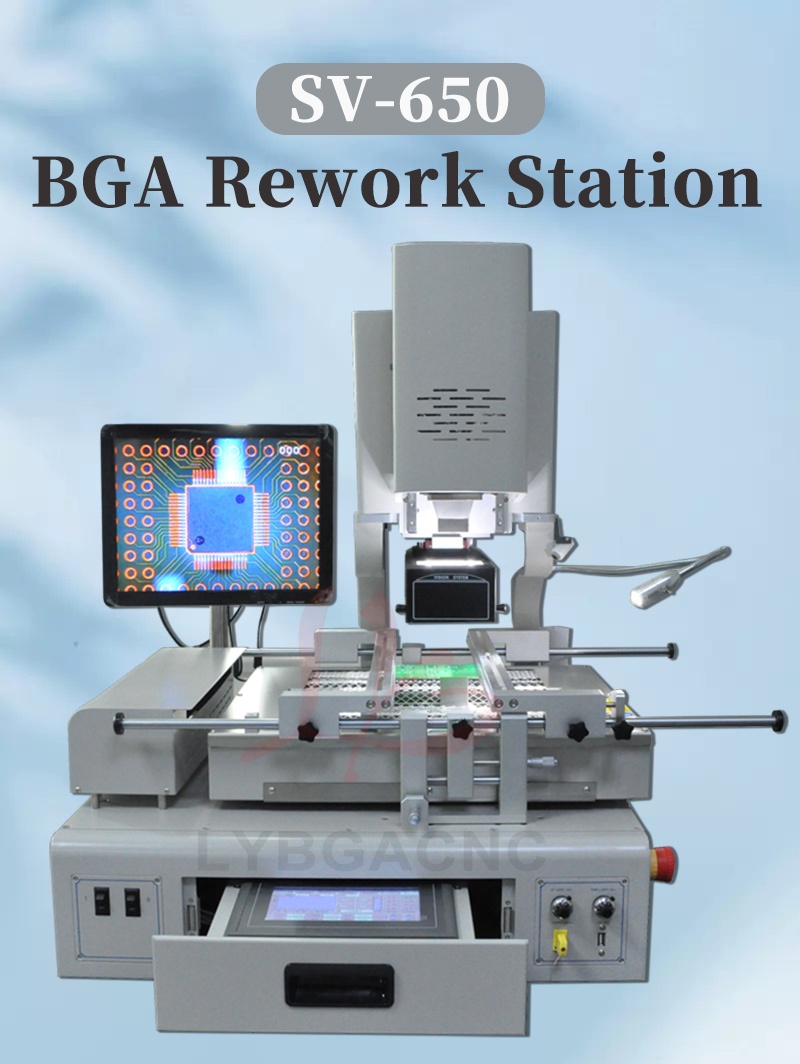

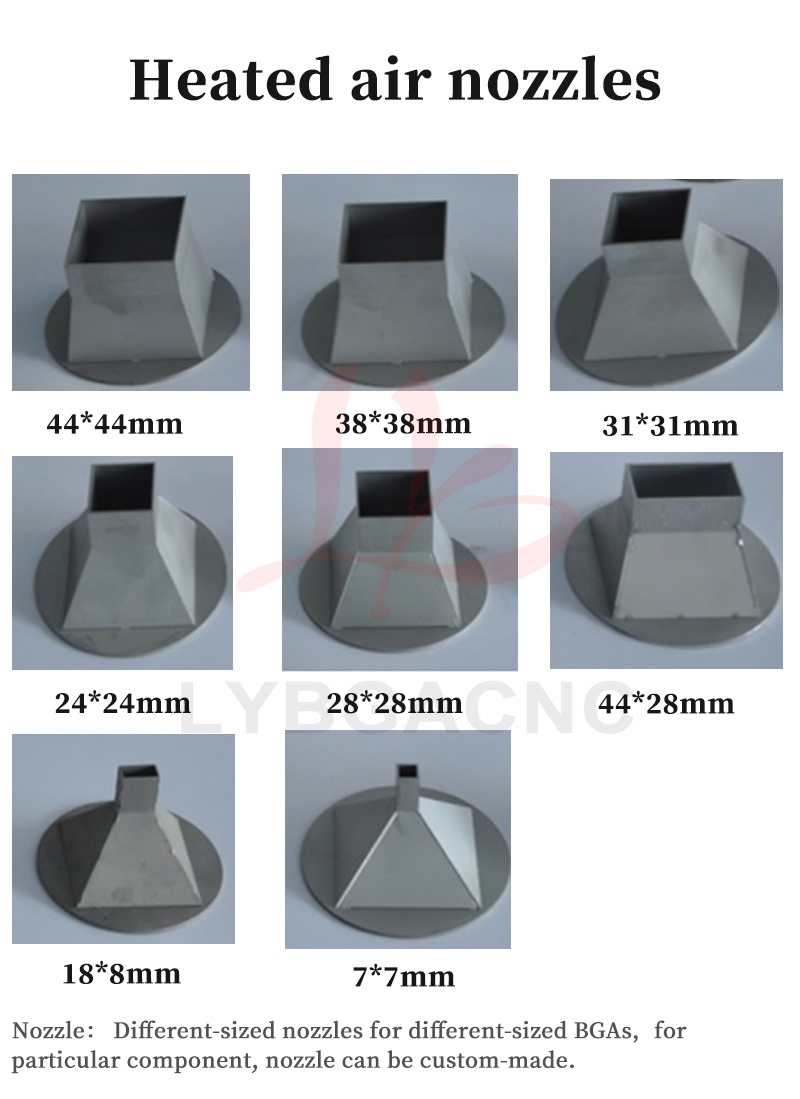

Fully Automated Shuttle Star BGA rework Station RW-SV-650 For Computer Server Reworking High-end Circuit Board Automatic Solder Focus 20X Optical Focus 70*70mm BGA Vacuum Pump 60° Angle Rotation

Product Detail

Product Tags

Fully Automated Shuttle Star BGA rework Station RW-SV-650 For Computer Server Reworking High-end Circuit Board Automatic Solder

Focus 20X Optical Focus 70*70mm BGA Vacuum Pump 60° Angle Rotation

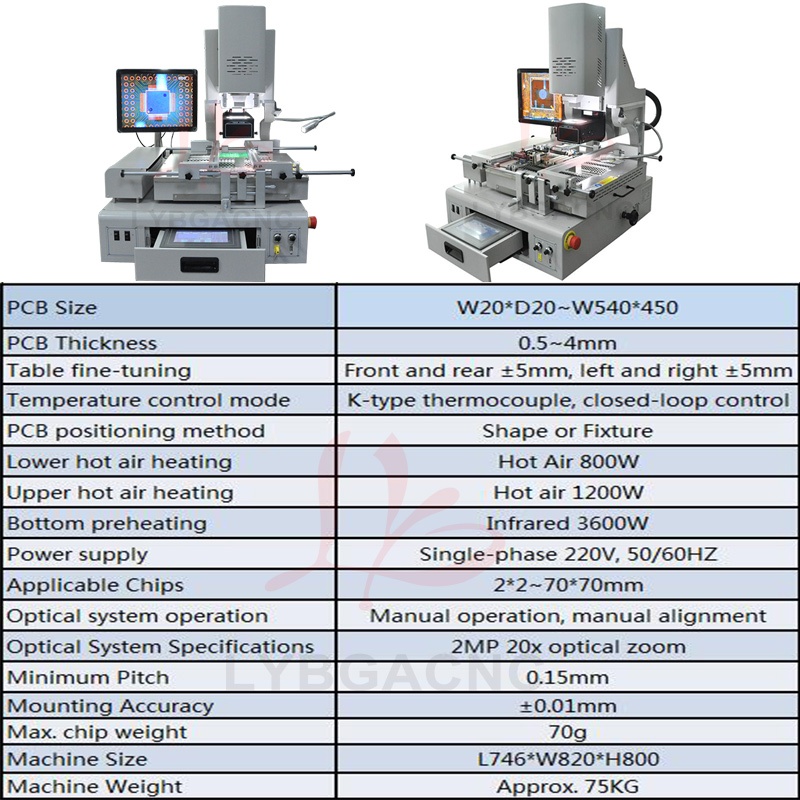

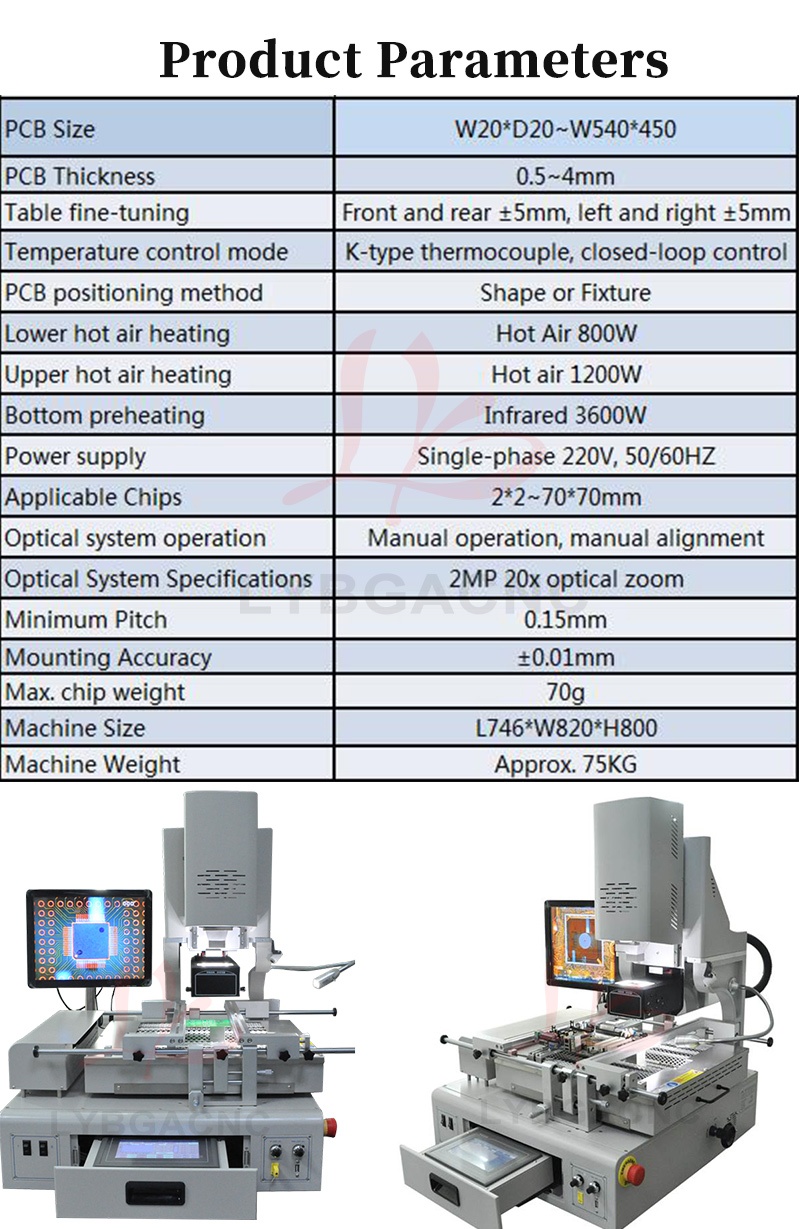

Product Parameters:

Max.control area 120mm x 120mm

Max.PCB thickness 4mm

Max.BGA size 70mm x 70mm

Min. BGA size 1mm x 1mm

Max. BGA weight 80g

Vision System Specifications

Max. visible area 40mm x 40mm

Min. Pitch .30mm

Micrometer Adjust Range: Front/Rear ±10mm Left/Right ±10mm

Rotation Angle 60°

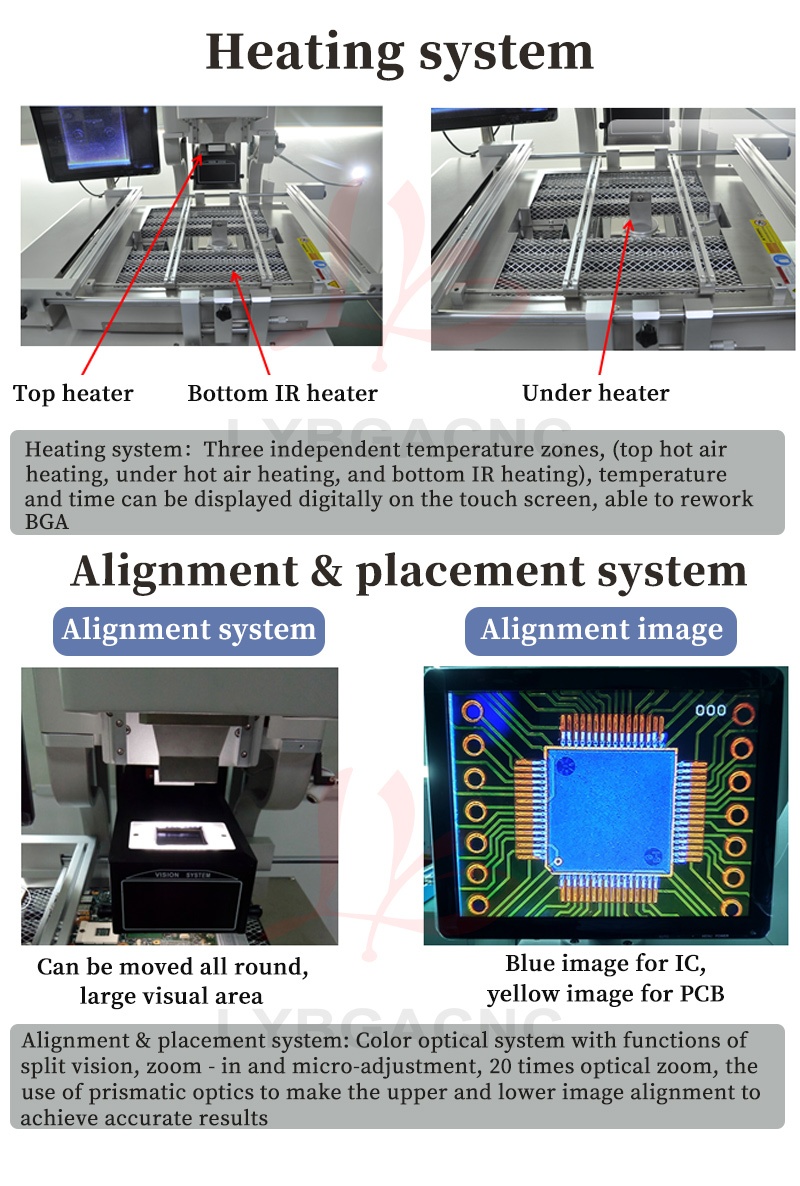

Thermal Specifications

Max.temp.for hot-air heater: 350°C

Max.temp.for IR heater: 400°C

Temperature control: 8-Stage Programmable Temperature Settings

Top heater power: 1200W

Spot heater power: 800W

Bottom IR heater power: 3600W

Dimensions & Power Requirements

Machine Dimension: 850mm (L) 750mm (W) 630mm (H)

Weight: Appox 92Kg

Power Supply: Single Phase. 220VAC. 50/60 Hz.

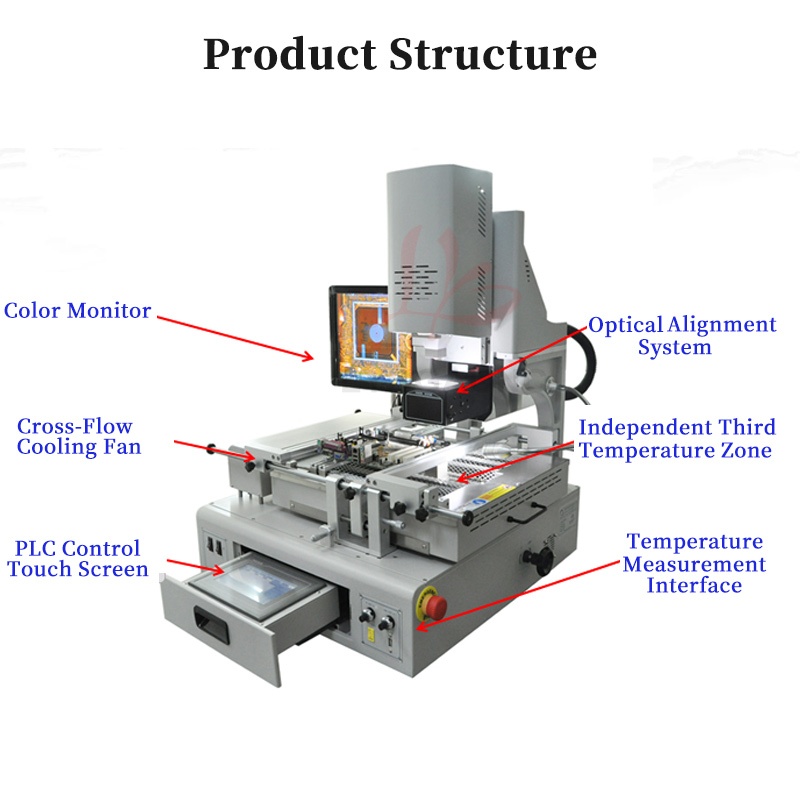

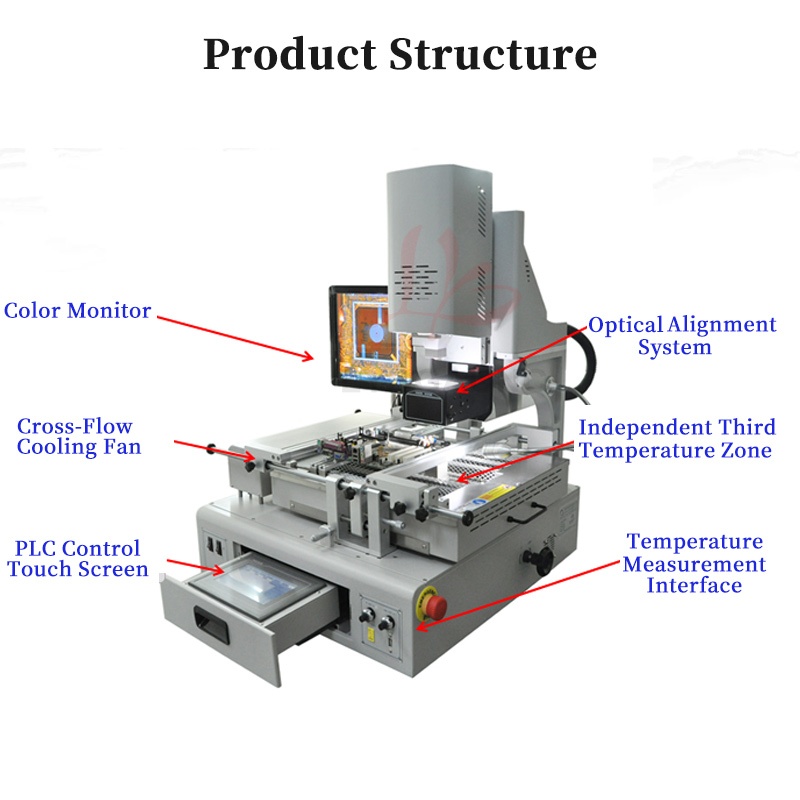

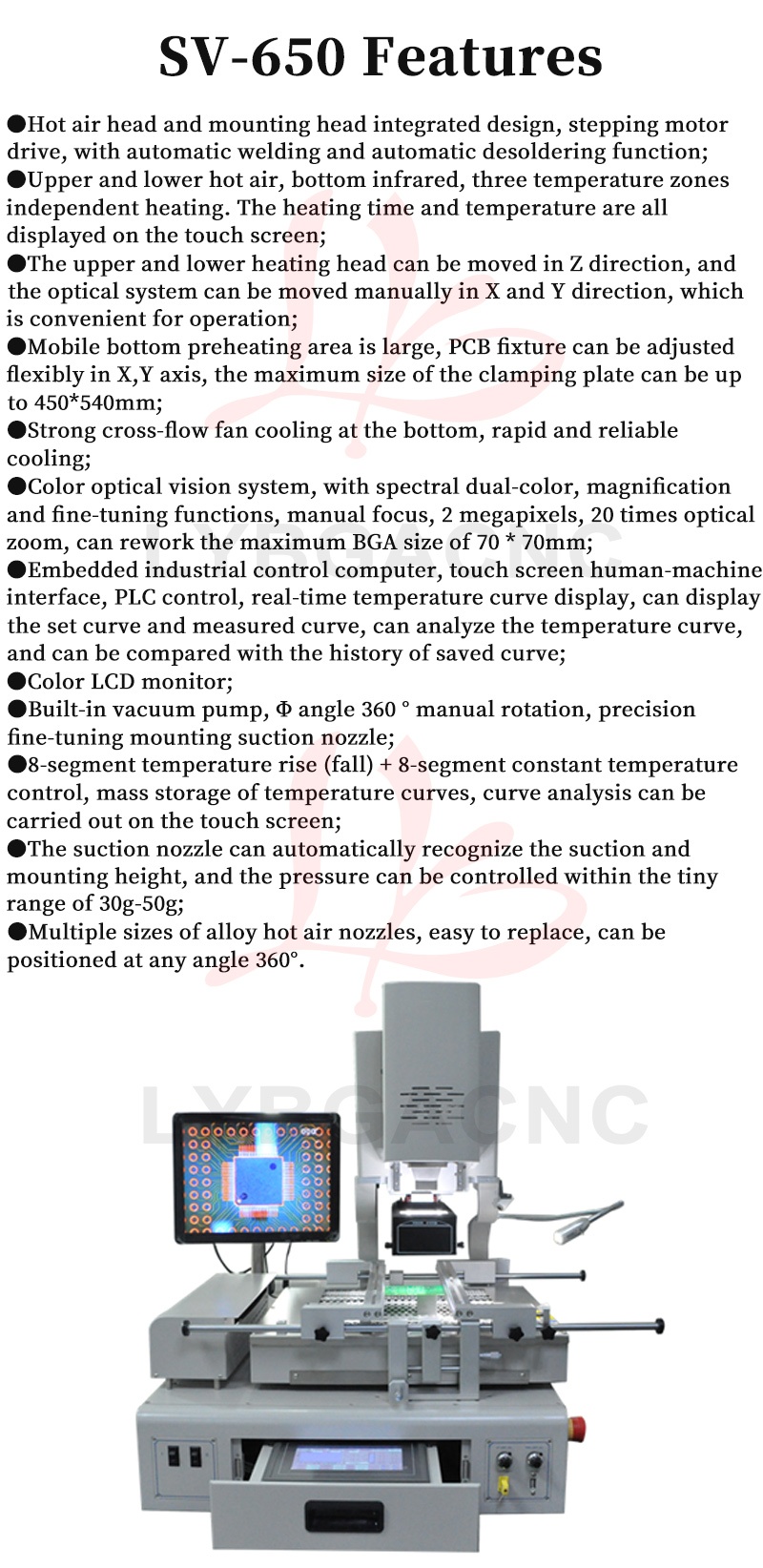

SV-650 Features:

●Hot air heater head and mounting head are designed 2 in 1, have both the auto soldering and

mounting function;

●Three heaters( top/spot hot air heater, bottom IR heater) heating independently, with auto protection

function while heating abnormally ,time and temperature can be displayed digitally on touch screen;

●Top heating system and cooling system are designed 2 in 1, temperature controlled accurately and

evenly.

Bottom heater is IR wave gilding heater plate, with high temperature glass, temperature increasing and

decreasing rapidly; profile setting accurate to protect the PCB from deformation, easy to solder, energy-

saving and environment friendly.

●Powerful cross flow fans cool the bottom heating area rapidly with stable speed;

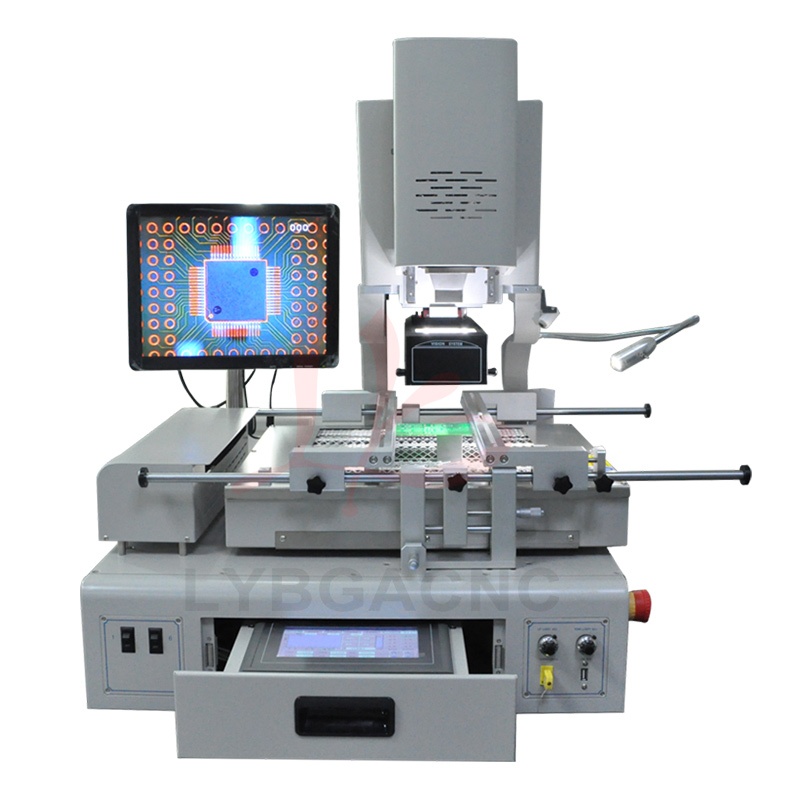

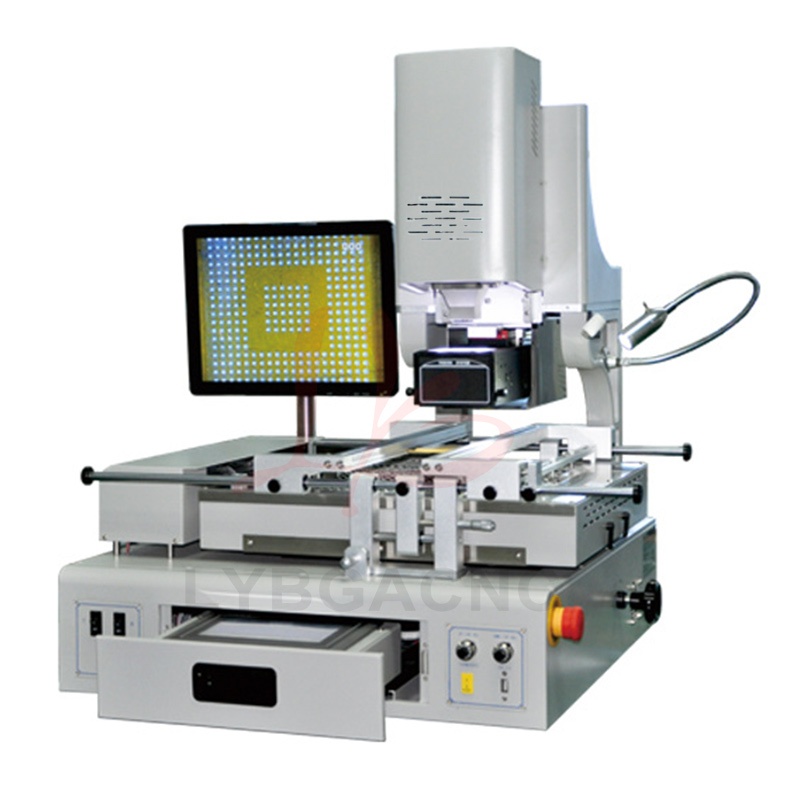

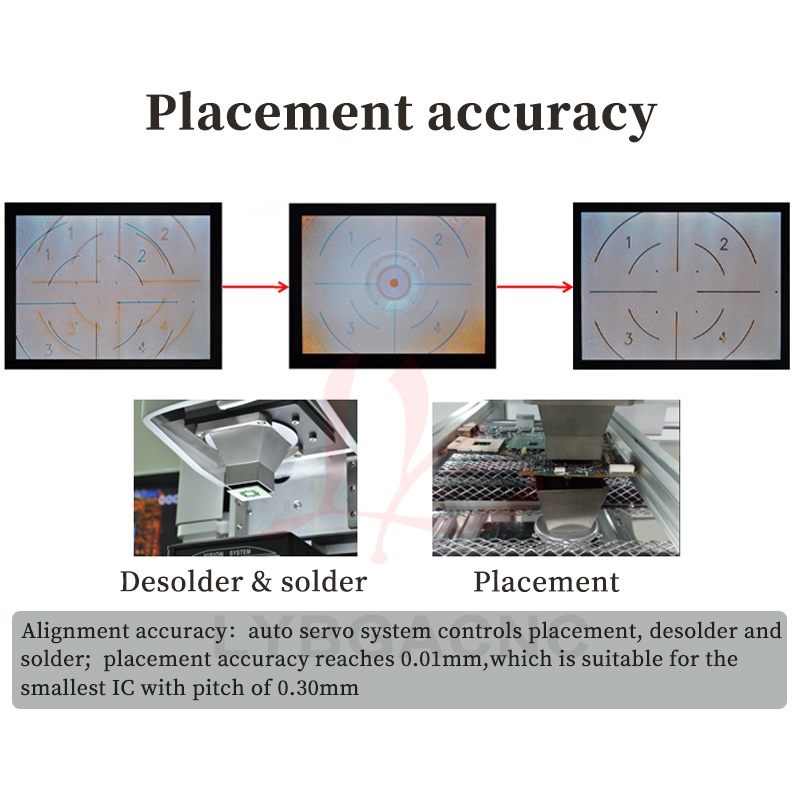

Color optical system with functions of split vision, zoom in/out and micro-adjust, equipped with

aberration detection device; with auto focus and software operation function, 1.3 million pixe/ high-

definition camera.

15”high-definition LCD monitor.

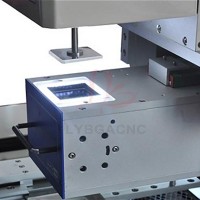

Both top and spot hot-air heating head can move z axis automatically, Optical vision system can move

along with X、Y axis automatically, install damping device ,easy operation.

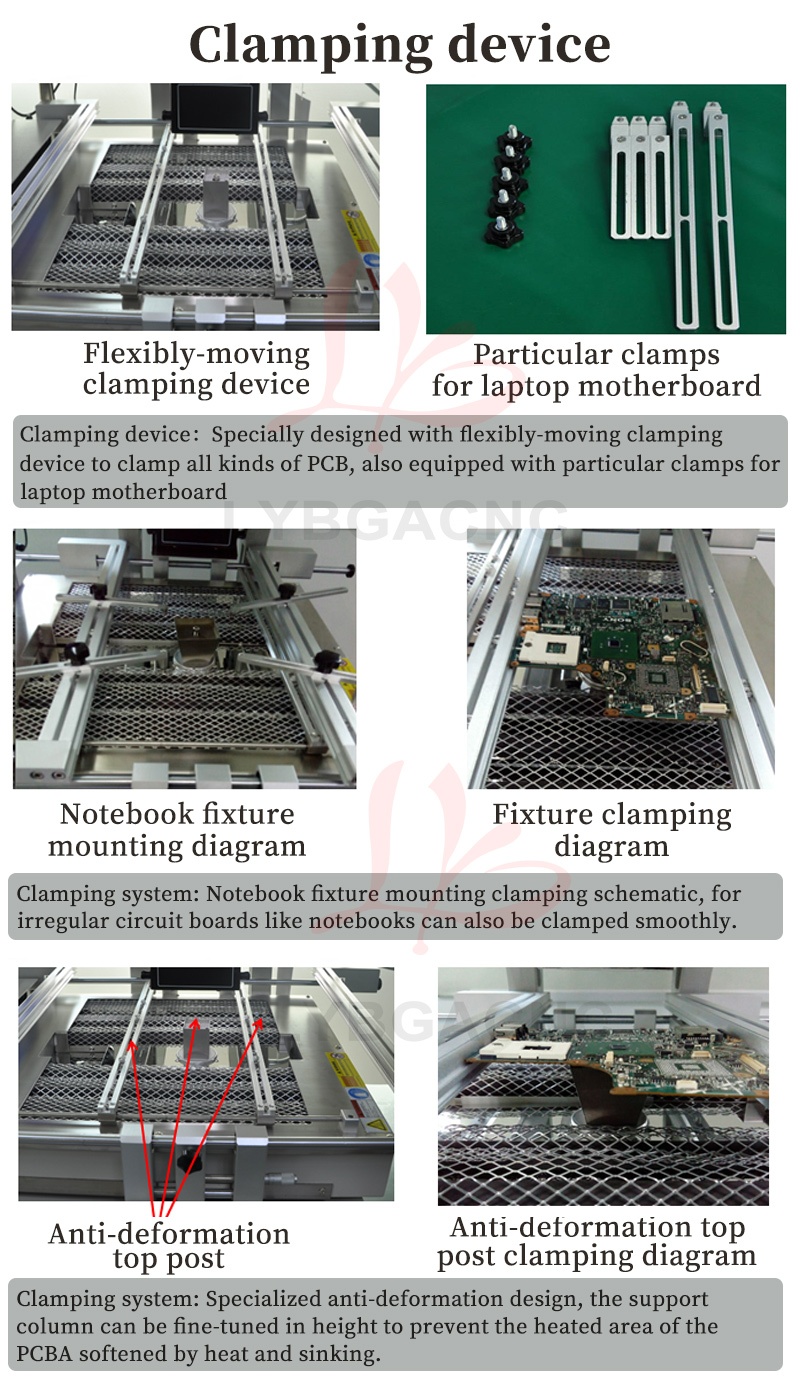

Large movable bottom IR heating area, PCB clamps can be adjusted along with X & Y table

flexibly, the max PCB size it can handle up to 550*500mm;

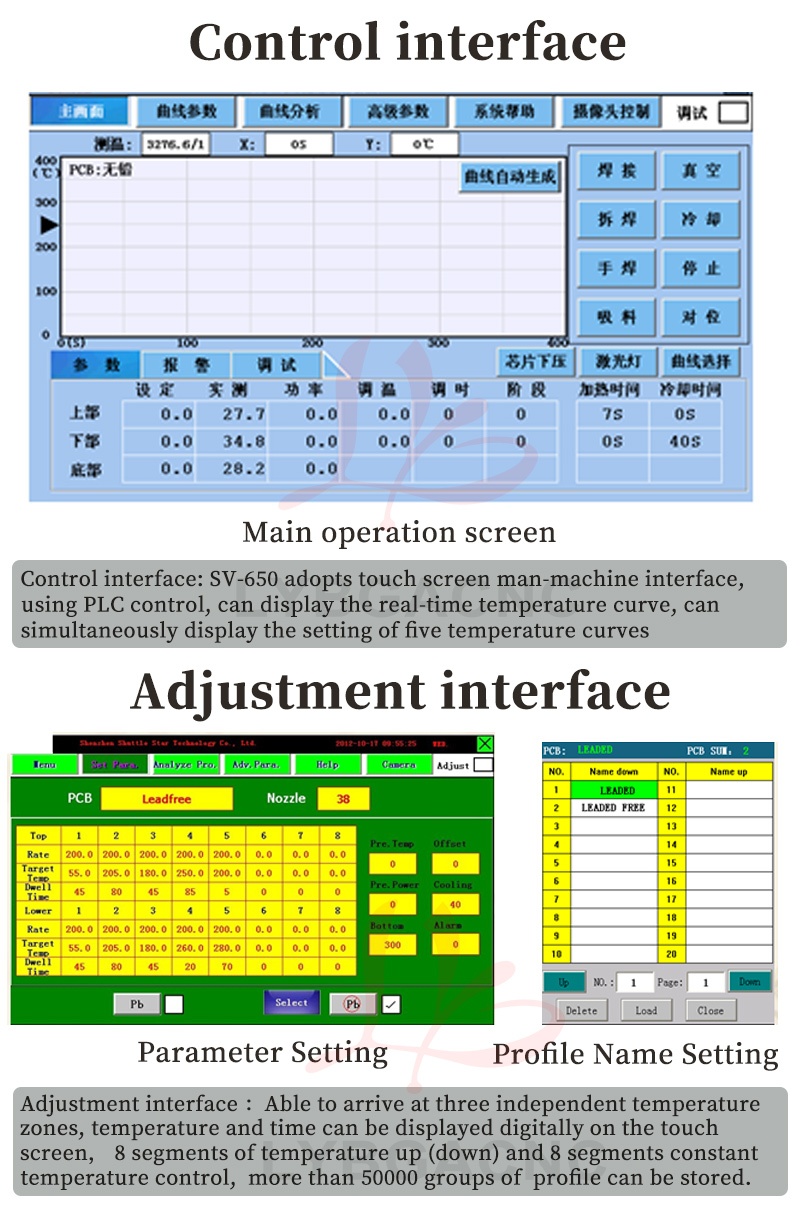

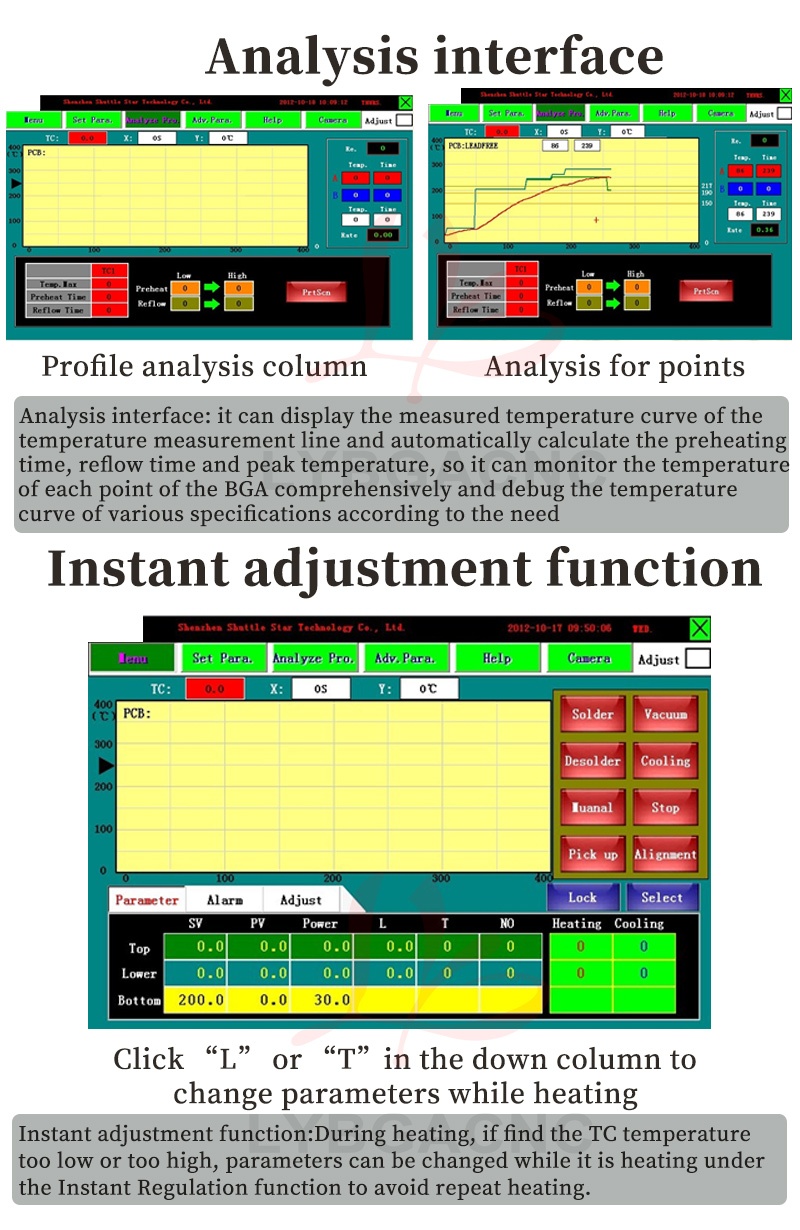

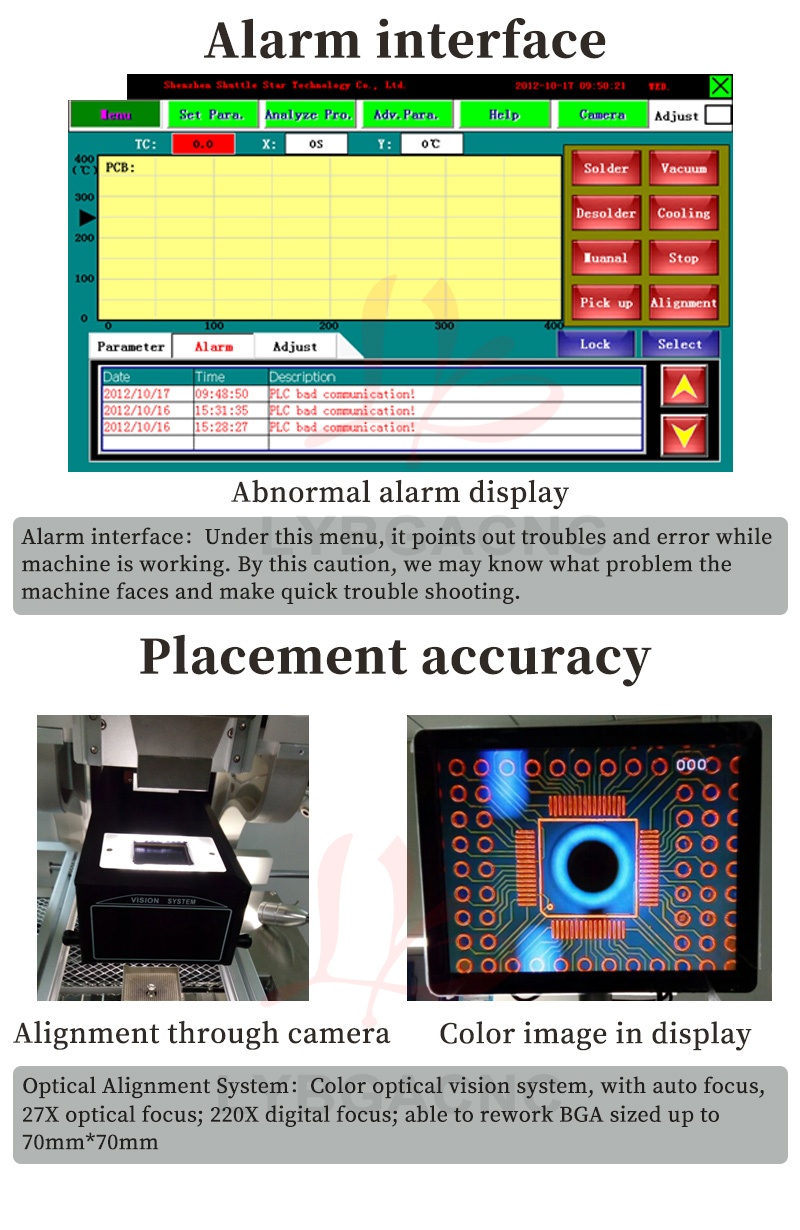

Embedded industrial computer, touch screen interface, PLC control, real-time temperature curve

display, able to display temperature curves and practical curves as the same time: can analyze the

practically-tested profile, and compare them with the history saved profiles;

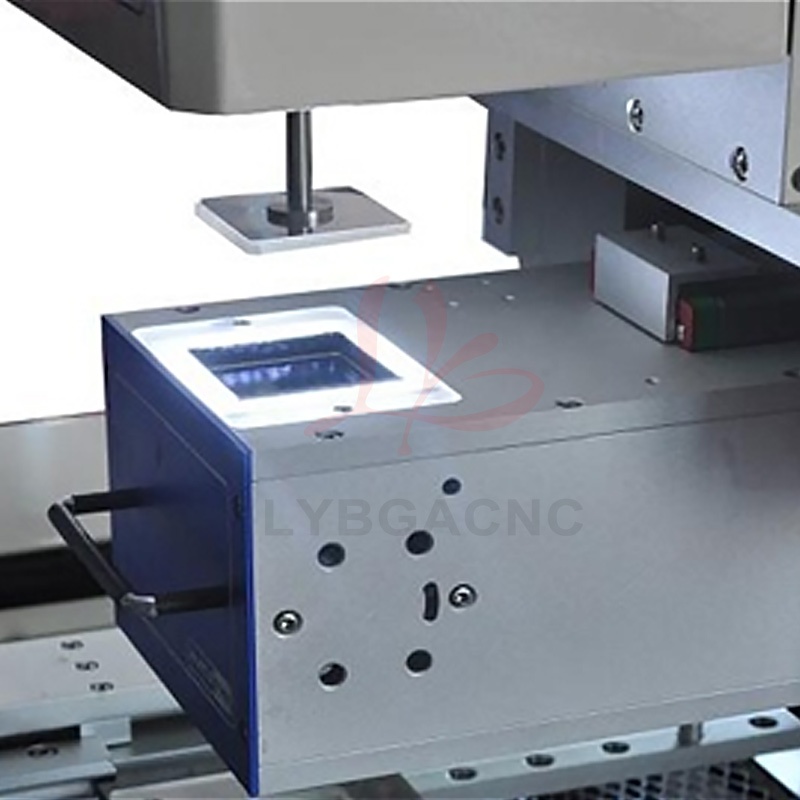

Built-in vacuum pump, 60° rotation in φ angle, mounting nozzle is micro-adjustable;

8 segments of temperature up(down) and 8 segments constant temperature control, profile saving is

unlimited in the industrial computer;

Suction nozzle can identify material and mounting height automatically, and can control the air

pressure within a small range ;

● Big size splint, equipped with deformation-proof supporting device, suitable for the accurate rework of

all kinds of PCB

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!