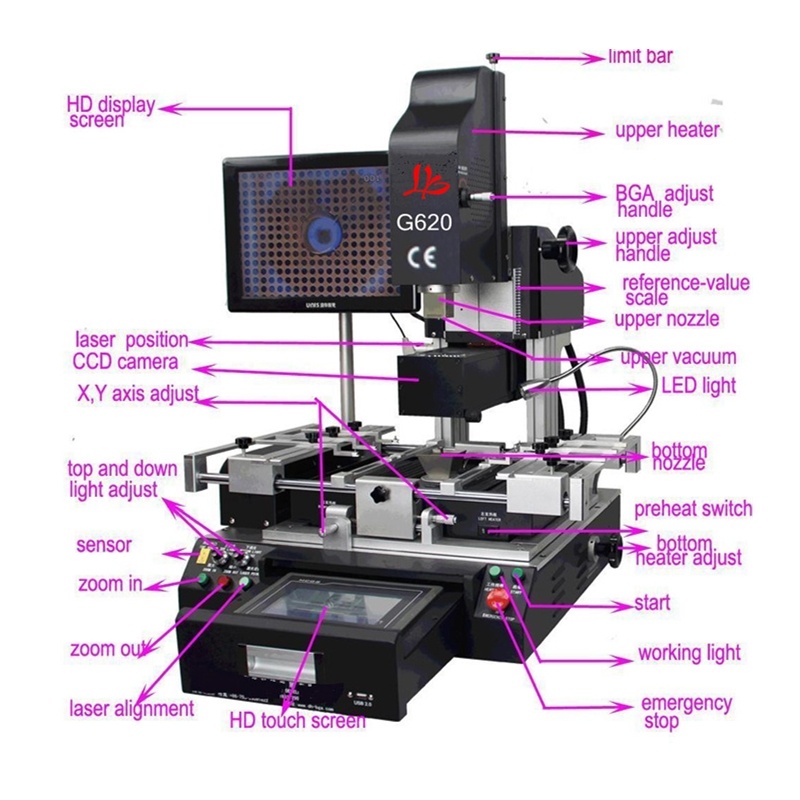

LY G620 drawer design optical align bga rework station 5300W

Product Detail

Product Tags

LY G620 drawer design optical align bga rework station 5300W

| Total Power | 5300W |

| Top heater | 1200W |

| Bottom heater | 2 nd:1200W 3 rd:2700W (Plus large fever area to adapt to all kinds of P board) |

| power | AC220V±10% 50/60Hz |

| Dimensions | L550×W580×H720 mm |

| Positioning | V-groove, PCB support can be adjusted in X direction with external universal fixture |

| Temperature control | K thermocouple (K Sensor)Closed loop |

| Temp accuracy | ±2±2 degree |

| PCB size | Max 400×380 mm Min 22×22 mm |

| BGA chip | 2*2-50*50mm |

| Minimum chip spacing | 0.15mm |

| External Temperature Sensor | 1 (optional) |

| Net weight | 70kg |

G620 Main Features

Embedded industrial PC, high definition touch screen, make the operation humanity, CPU control, and instant curve analysis function. Real-time display settings and actual temperature curve, which can also be used to analyze and correct the curve if necessary.

High precise k-type thermocouple closed-loop control and automatic temperature compensation system, with CPU and temperature module to enable precise temperature deviation to add and subtract 2 degrees. Meanwhile, external temperature measurement connector enables temperature diction and accurate analysis of real time temperature curve.

V-groove PCB works for rapid, convenient and accurate positioning, which can meet all kinds of PCB board of positioning.

Flexible and convenient removable fixture on the PCB board can protect the PCB fringe devices from damaging and transmuting. It can also adapt to various BGA ‘s reworking.

Various sizes of BGA alloy nozzles, which can be adjusted 360 degree for easily installation and replacement.

Three independent heaters: Three temperature areas can independently heat and they are multiple temperature control, which can ensure best integration of different temperature areas. Heating temperature, time, slope, cooling and vacuum can all be set in the human-machine interface.

There are 8 stage temperature controls up and down. Massive storage of temperature curves which are accessible at any time according to different BGA. Curve analysis, setting and adjustment are also accessible via touch screen. Three heating areas adopt independent PID calculation to control heating process to enable more accurate temperature.

High power cross-flow fan to enable fast cooling of PCB board and prevent PCB from deformation. There are also internal vacuum pump and external vacuum chuck, which can help to fetch the BGA chip;

Collocating with sound control “early warning” function. It can warn workers to make some relative preparation 5-10 seconds before the completion of uninstalling or welding. Cooling system will start after vertical wind stopped heating. When the temperature drops to normal temperature, the cooling process will stop automatically, so that the machine will not be aging after temperature heated up.

Rocker controller for controlling the upper heater goes up and down freely, and it also has the function for zooming the picture.

CE certificate,equipped with emergency stop switch and automatic power-off protection device when emergency happens.

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!