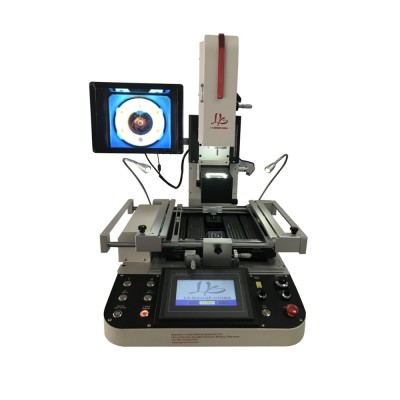

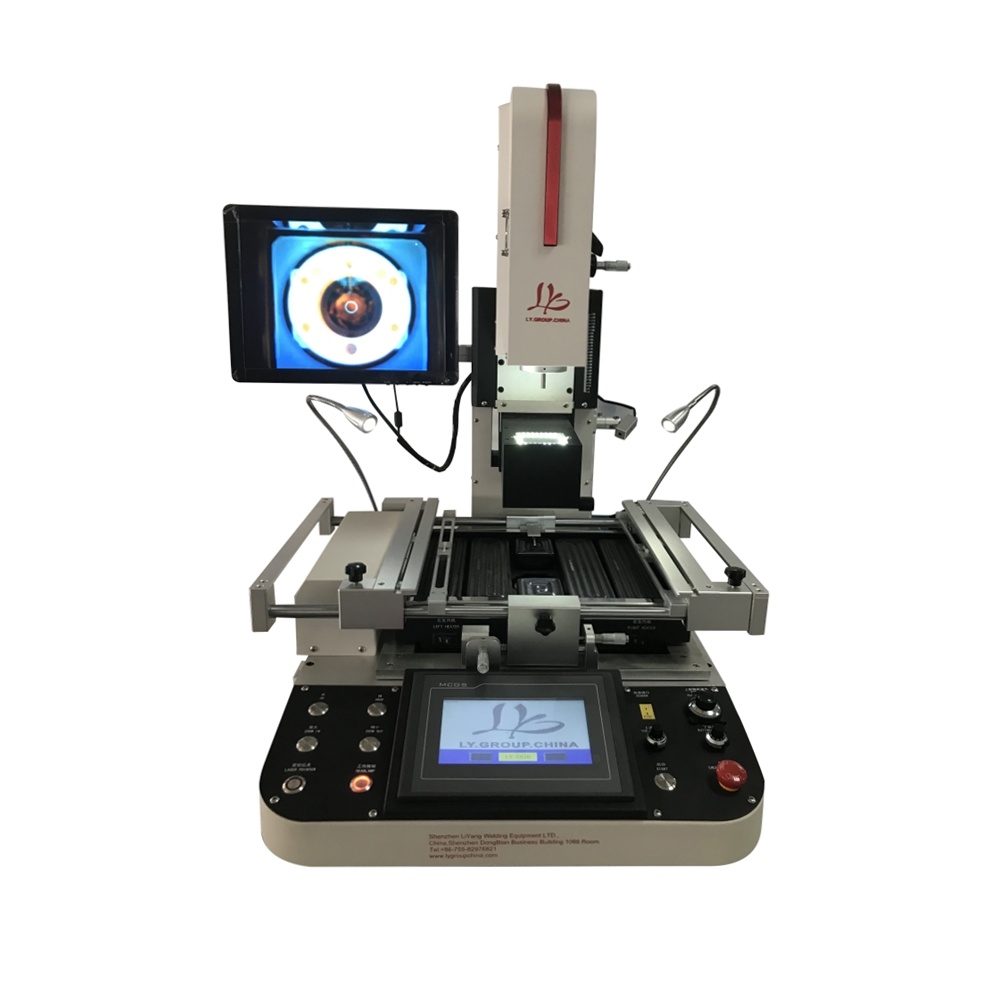

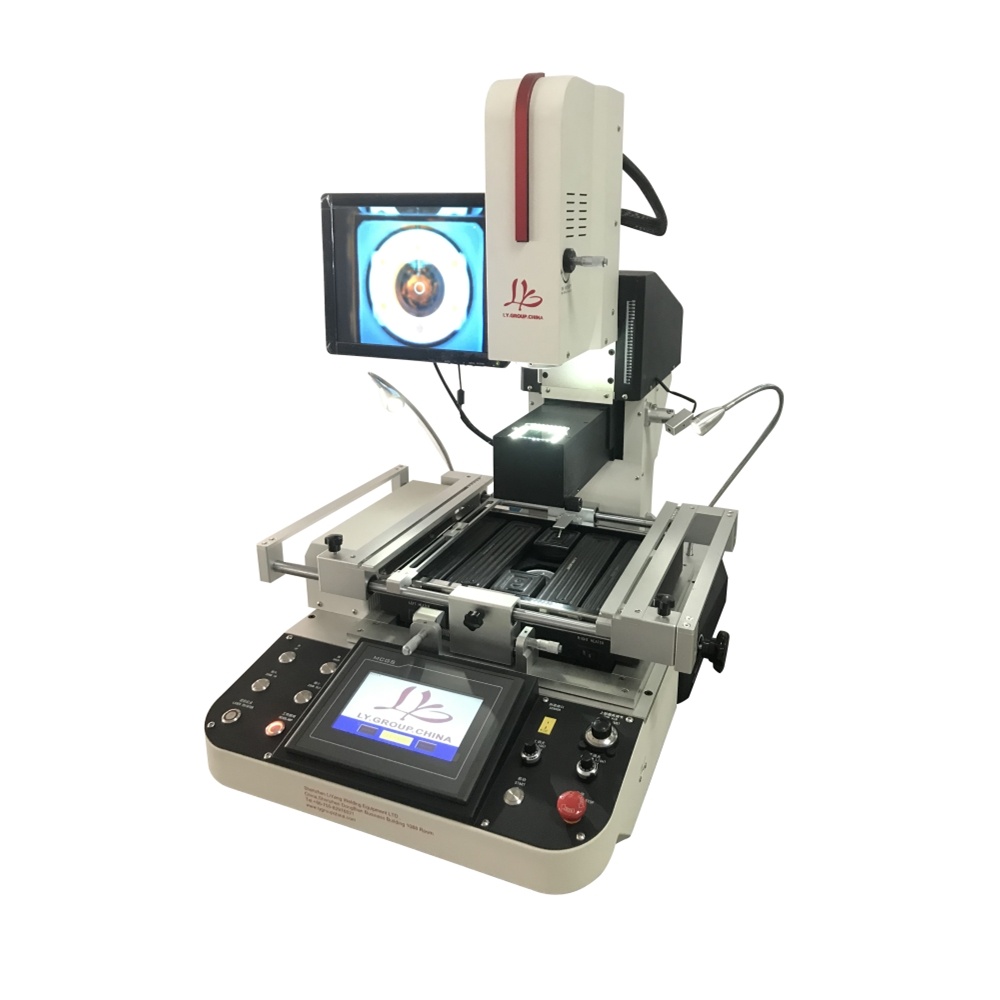

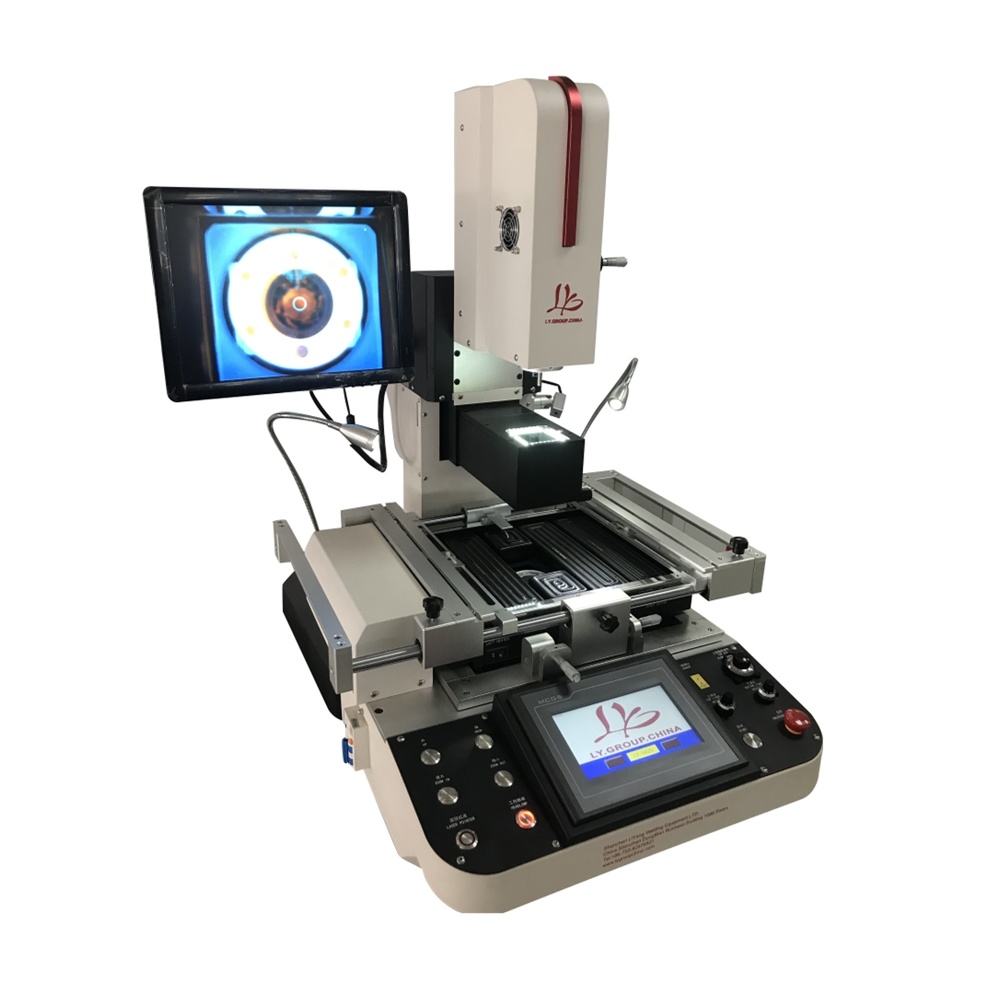

New Version LY G820 G-820 Universal Semi-automatic Compact Align BGA Rework Station For Server Notebook Laptops/Game Consoles Mobiles 220V 5300W

Product Detail

Product Tags

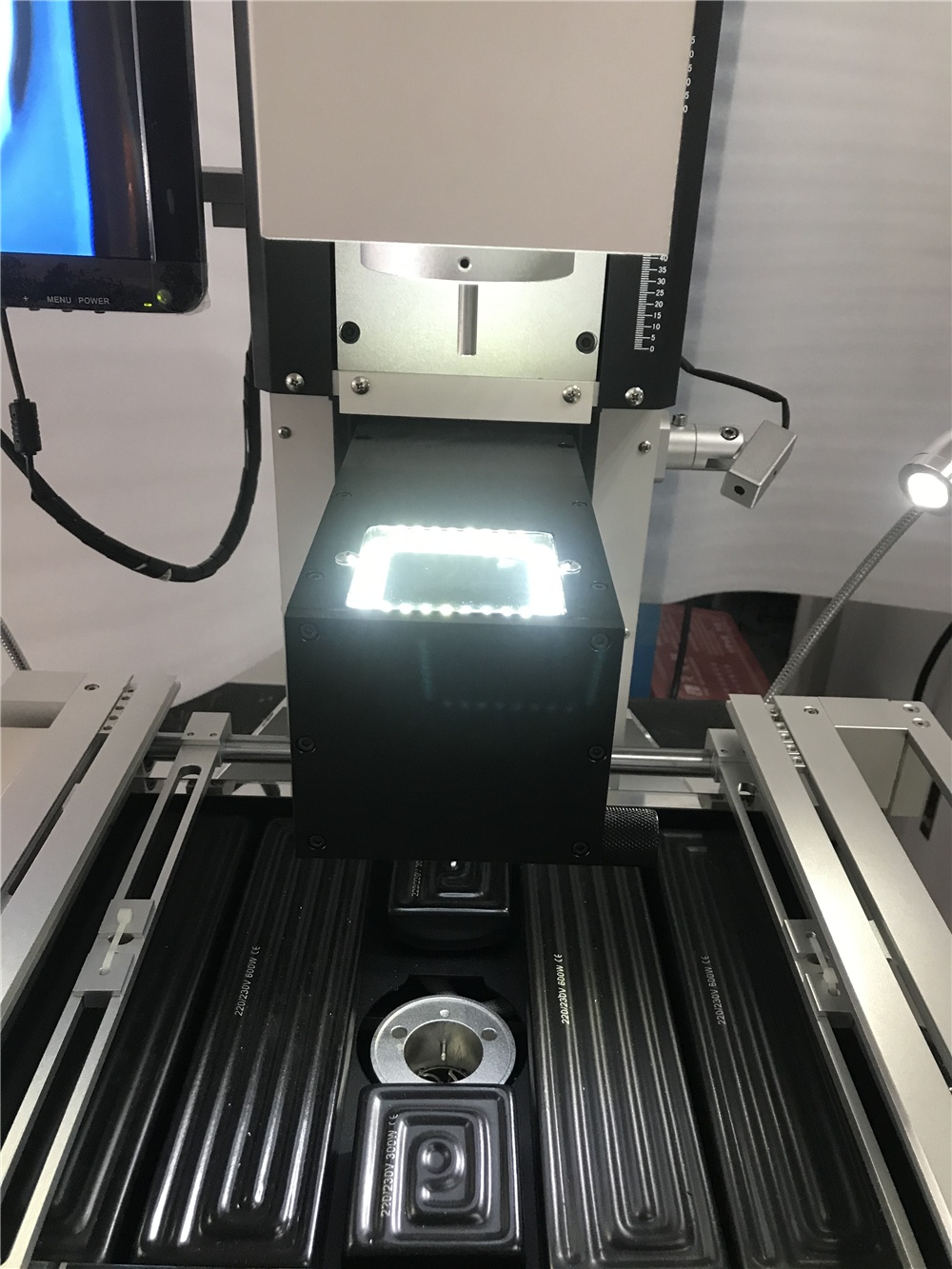

New Version LY G820 G-820 Universal Semi-automatic Compact Align BGA Rework Station For Server Notebook Laptops/Game Consoles Mobiles 220V 5300W

Description:

1. High definition touch screen man-machine interface, PLC control, instantaneous curve analysis function, real-time display of set and measured temperature Curve, and the curve can be analyzed and corrected.

2. High precision K-type thermocouple closed-loop control and automatic temperature compensation system, combined with PLC and temperature module to realize temperature control

At the same time, the external temperature measurement interface realizes the precise detection of temperature and

Accurate analysis and calibration of measured temperature curve

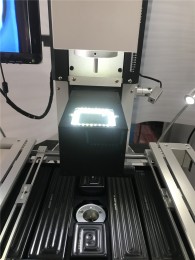

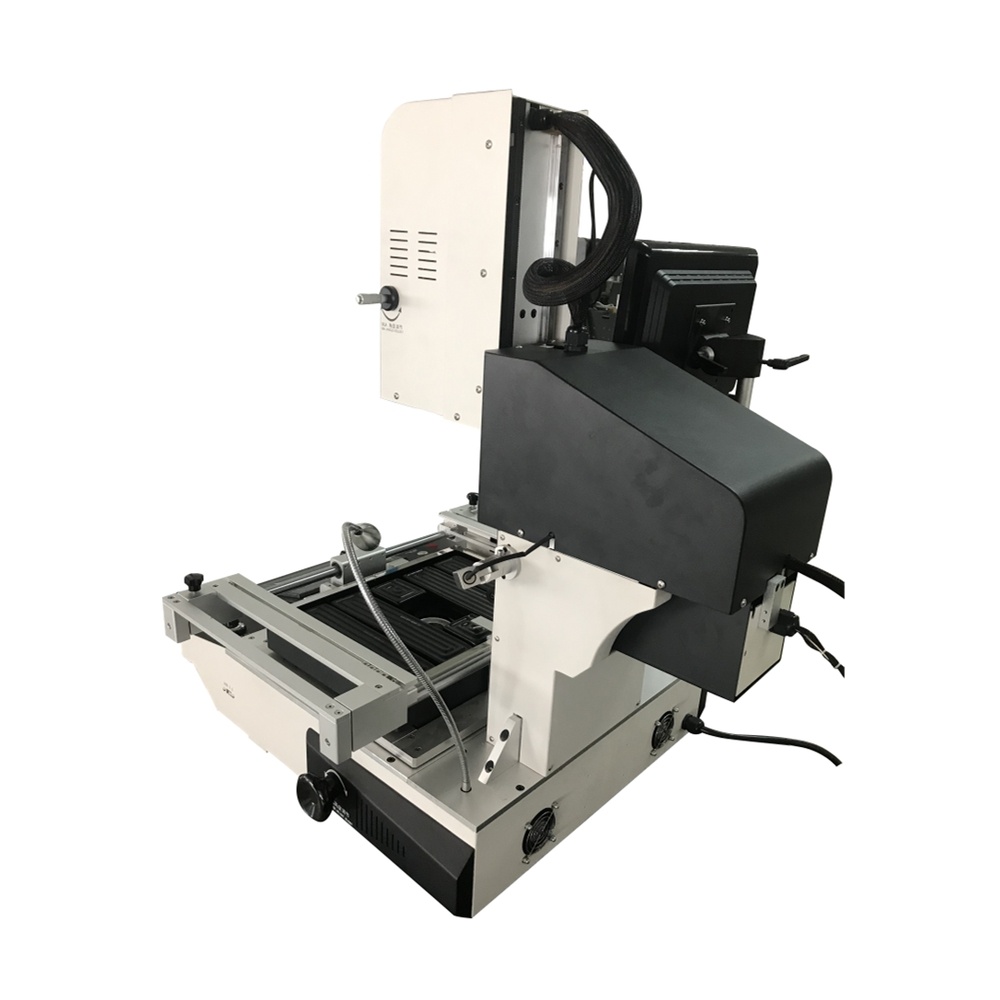

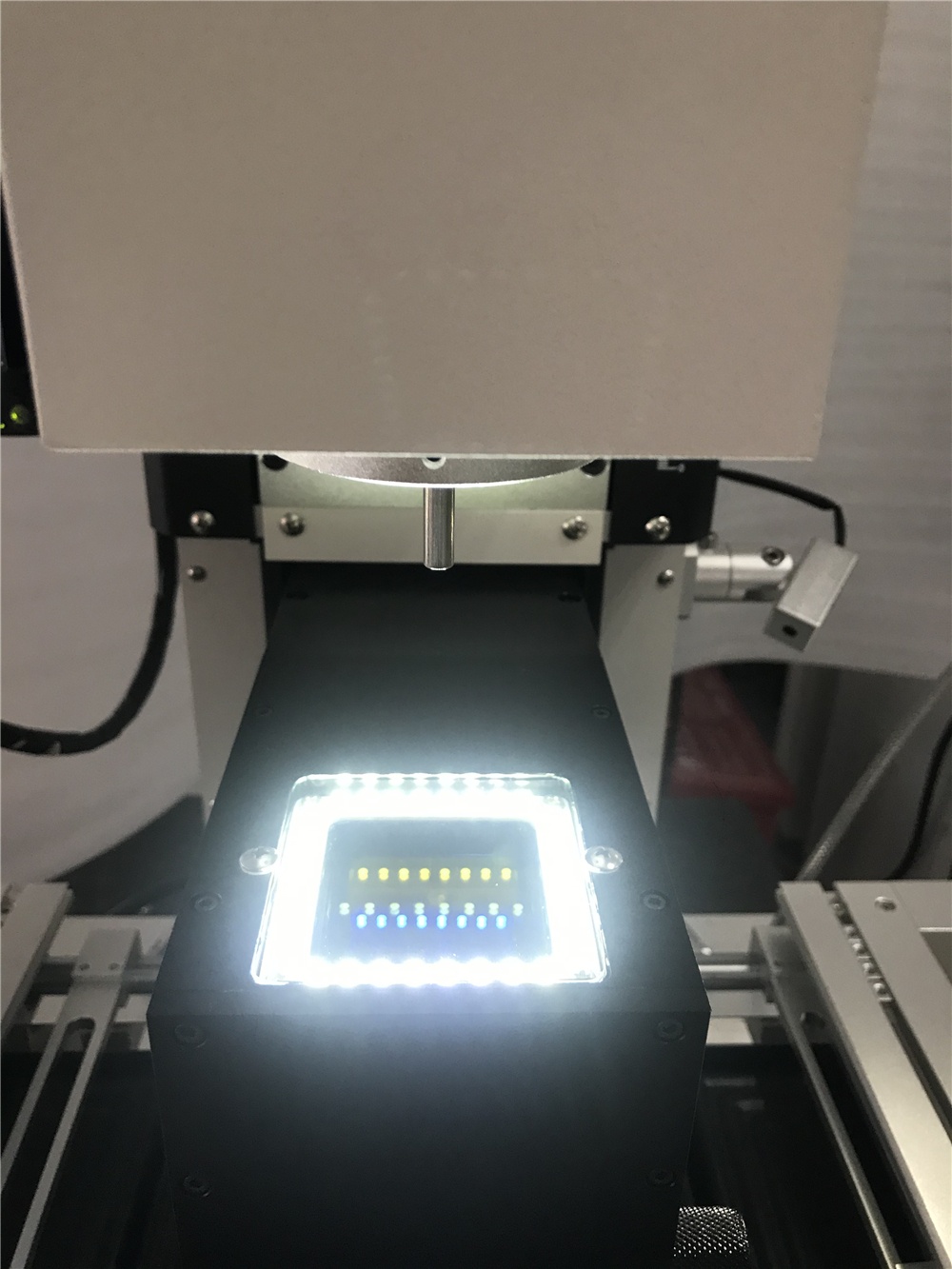

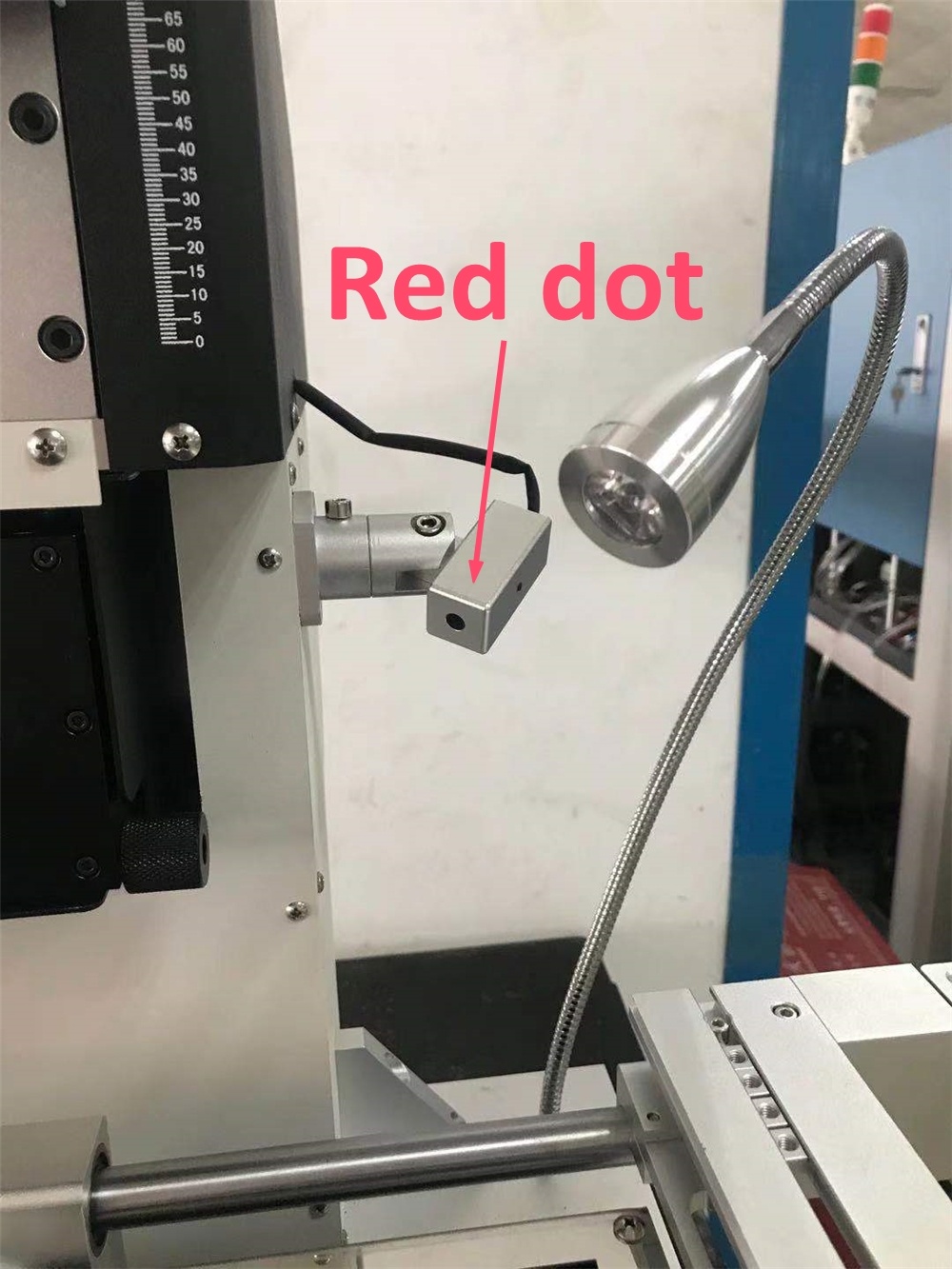

3. High precision digital video alignment system is adopted, V-shaped slot is adopted for PCB positioning, and linear sliding seat is adopted to make x, y

The z-axis can be fine tuned or quickly positioned, which is convenient and accurate to meet different PCB layout methods and different sizes

Positioning of small PCB board

4. The flexible and convenient movable universal fixture can protect the PCB board and prevent the damage of PCB edge devices and PCB

Deformation, and can adapt to the repair of various BGA package sizes;

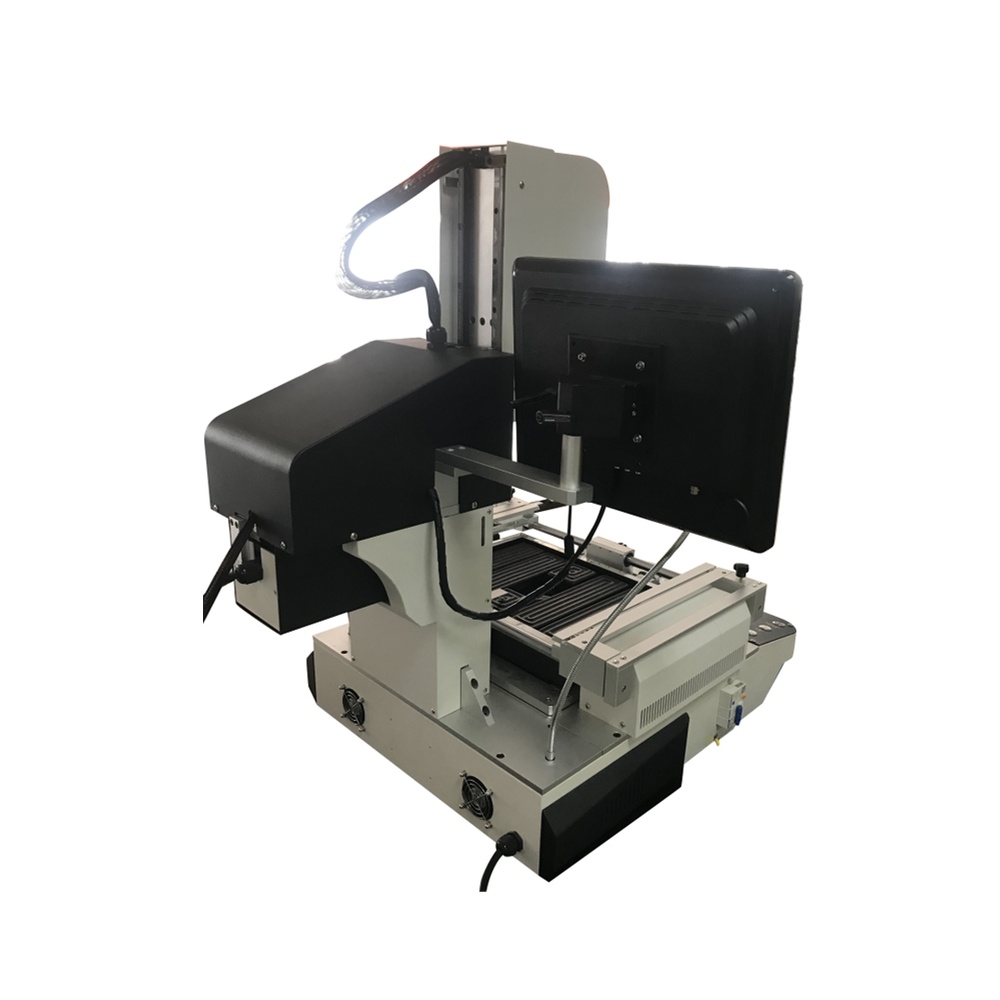

5. It is equipped with alloy air nozzles of various specifications, which can be rotated and positioned 360 degrees, which is easy to install and replace;

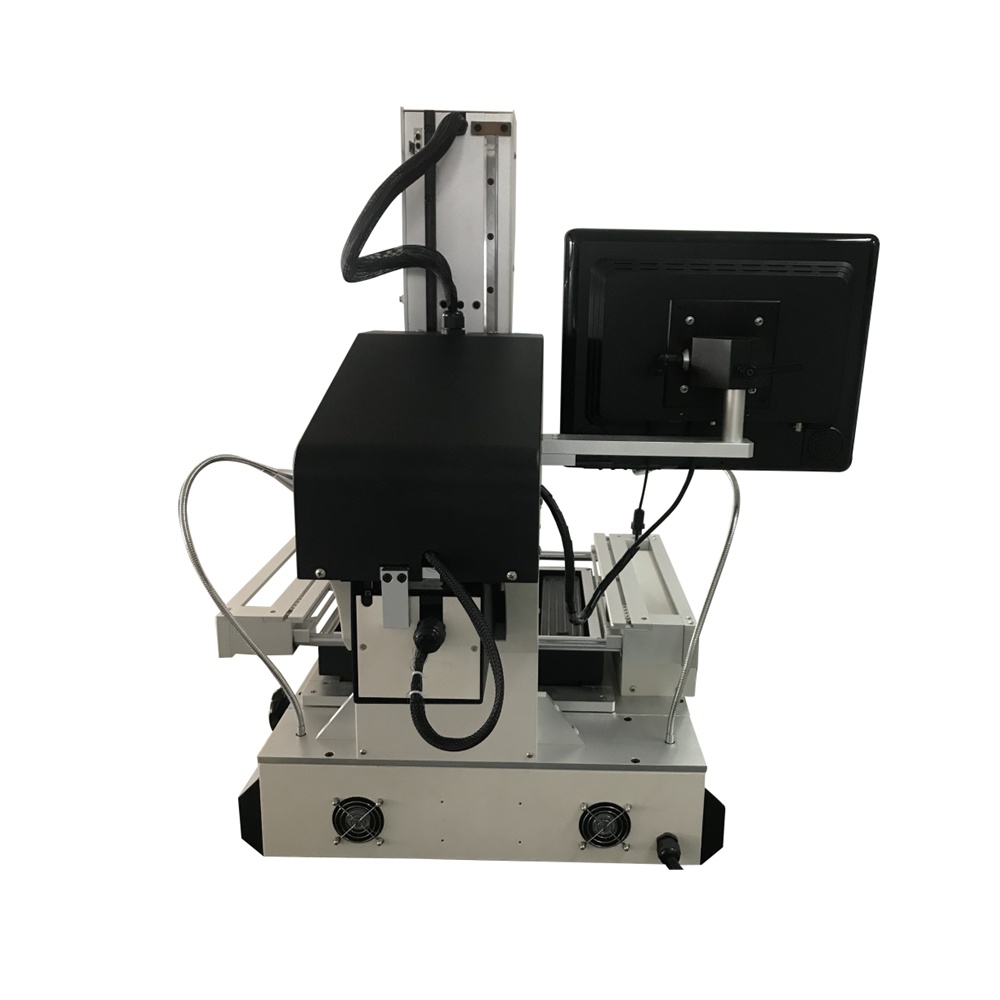

6. The upper and lower temperature zones are heated independently, and the three temperature zones can carry out multi group and multi-stage temperature control at the same time to ensure the synchronization of different temperature zones

Achieve the best welding effect. Heating temperature, time, slope, cooling and vacuum can be set on the man-machine interface.

7. 8 sections of temperature control can be set in the upper and lower temperature zones, and the temperature curve can be mass stored, which can be adjusted according to different BGA at any time

With, curve analysis, setting and correction can also be carried out on the touch screen; The three heating zones are controlled by independent PID algorithm

Heating process,

8. More uniform temperature rise and more accurate temperature;

9. Use high-power cross flow fan to quickly cool the PCB board to prevent PCB board deformation, mounting, welding and disassembly

Realize intelligent automatic control of process;

10. It has a USB interface, which can easily download the current curve and store it in the USB flash disk, and plug in the mouse to use the extended touch control

Screen usage time

11. Configure the voice control “early alarm” function. Warn the operators to make a warning by voice control 5-10 seconds before the completion of disassembly and welding

Off preparation. After the upper and lower hot air stops heating, the cooling system starts and automatically stops cooling when the temperature drops to normal temperature. ensure

The machine will not age after heating up!

12. CE certified, equipped with emergency stop switch and automatic power-off protection device in case of emergency.

Specification:

Total power 5300w

Upper heating power top heater 1200W

Lower heating power bottom heater second temperature zone 1200W, third temperature zone 2700W (add large heating area to adapt to various PCB boards)

Power AC220V ± 10% 50 / 60Hz

Dimensions l610 × W920 × H885 mm

Positioning V-shaped card slot, PCB support can be adjusted in X direction and equipped with universal fixture

Temperature control K-type thermocouple (k sensor) closed loop

Temp accuracy ± 2 degrees

PCB size Max 380 × 370 mm Min 22 × 22 mm

Applicable to BGA chip 2 * 2-50 * 50mm

Applicable to the smallest chip

spacing

Minimum chip spacing 0.15mm

1 external temperature sensor with external temperature measurement port (optional)

Packing list:

Upper nozzle 31 * 31, 38 * 38, 41 * 41mm, lower nozzle 35 * 35, 55 * 55mm( Total 5 pcs)

Aluminum Fixture * 6 pcs

M5 handle * 6pcs

vacuum suction cups * 5pcs

1 kit of vacuum Stainless suction nozzle (5pcs)

Temperature Sensor * 1

Tweezers * 1

Wrench * 3

Machine meter screws * 6

Packing: wooden case

Box Size: 104x70x78cm

Gross weight: about 100kg

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!