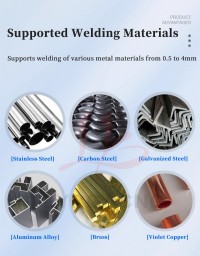

Fiber Laser Welding Cutting Machine LY-X3 1000W Multifunctional Mini Air-cooled Handheld Portable Welder Cutter for Metal Energy Saving Single Pulse Energy With Single Wire Feeder

Product Detail

Product Tags

1. Operators must carefully read and master this document, and receive training before taking up their posts

2. The welding platform cannot be shared with other welding machines, and the equipment must be effectively grounded

3. Air pressure 0.1-0.7 MPa, flow rate 10-15 l/min, energy-saving gas meter not available

4. The welding gun should be kept at a 45 ° welding angle as much as possible and should

not be welded vertically to avoid damage to the laser caused by light reflection

5. Try to face the gun head downwards to prevent dust from falling on the protective lens

6. Set switch air delay to extend the lifespan of protective lenses

7. In the same parameter state, if there is a change in welding effect, stop welding, check the

status of protective lenses and other equipment, do not act recklessly to avoid damage to high-value lenses

8. If the welding copper nozzle turns red and hot, stop welding and check if the laser is completely emitted from the center of the nozzle circular hole. If not, adjust the laser center offset parameter or remove the reflector cover and adjust the machine screw to ensure that the laser is completely emitted from the middle of the copper nozzle circular hole. In general, the redness and heat of the copper nozzle are caused by some laser hitting the inner wall of the copper nozzle

9. If there is a red light that does not come out after pressing the switch, it is generally due to the unstable connection of the safety lock clip

10. If there is red light, wire output, or no light output after pressing the switch, check if the

laser wiring is firm, or if it is caused by the laser alarm

11. When replacing the lens and pulling out the drawer, seal the opening with masking tape in a timely manner to prevent dust from entering

12. When using alcohol to wipe the lens, it is necessary to use anhydrous alcohol (analytical grade) and a dust-free cotton swab to wipe from one side to the other in one direction. Do not wipe back and forth or spiral wipe. If there is dust that cannot be wiped off or black spots or pits, replace the lens immediately

13. The welding gun has a precise light path inside, which should be handled with care and not dropped. There is electricity, gas, and light path inside the welding torch wire, and it cannot be heavily pressed or bent. After use, please securely place the welding torch and welding torch wire on the equipment rack

14. After prolonged use, dust may accumulate and affect heat dissipation, requiring regular cleaning

15. Before welding, check the position of the red light. The welding wire must be located in the middle of the red light, otherwise the weld bead will not be aesthetically pleasing

16. The wire feeding speed is generally set at around 60cm/minute. If the welding wire is intermittently discharged, check whether the wire feeding pipe is wrapped or bent too much. Smooth the wire feeding tube can generally be avoided. Dirty and dirty inner walls of the wire feeding tube can also be caused. If necessary, cut the wire feeding tube short or replace it with a new one. Aluminum wire feeding is prone to wire blockage. It is recommended to use 5 series 1.6mm diameter welding wire, and if necessary, replace the graphite wire feeding tube or PTFE wire feeding tube.

Parameter:

Model: LY-X3

Laser Power:1000W

Metal welding single Pulse Energy: 96J/150J

Core components: Laser source

Key selling points:

Energy saving

Single pulse energy:

96J/150J

Pulse width:

0.1-20MS

Wavelength:

1070+_10nm

Focal spot diameter:

0.6-0.5nm

Dimensions:

630*360*570mm

Warranty: 1 Year

FQA:

Q1. I only have one idea, can you offer your own solutions?

R1: We have technicians with more than 10 years of work experience, we can design according to your idea of equipment. During the developing process, in order to ensure that the product meets your needs, we will confirm with you one by one.

Q2. What standards does your equipment meet?

R2: The quality of our equipment meets international standards, ISO9001 quality system standards, and the quality of our manufacture equipment meets international standards.

Q3. My schedule is urgent. What is your usual delivery time?

R3: We can deliver goods on the same day you place order at the soonest for the standard products at stock. Of course, the specific delivery time is related to your needs, in order to ensure the delivery time, we have special emergency teams and plans for R&D, non-standard or urgent equipment.

Q4. Can you manufacture the equipment according to our samples?

R4: Yes, we support door-to-door sample collection and customize equipment according to your sample.

Q5. Due to poor quality of many manufacturers in the past, how about your quality?

R5: The quality of equipment is the most basic guarantee of the company, we promise that the equipment will be returned and replaced because of quality problems! At present, there is no problem with our equipment working for more than 30 years, in addition, we will replace it for free if there is any problem within one year, and we provide lifetime after-sales service.

Q6. What standards does your equipment meet?

R6: The quality of our equipment meets international standards, ISO9001 quality system standards, and the quality of our manufacturing equipment meets international standards.

Q7. I have my own product drawing, can you produce the equipment according to the drawing?

R7: We can design the equipment according to your product drawings, in order to ensure the quality of the equipment, we will provide free sampling services.

Q8. We are not able to use it. Do you have any technical instructions?

R8: We provide complete free after-sale service and training service, like on-site installation and use etc.

Q9. Your equipment at hand is not suitable for us, can you customize it for us?

R9: Yes, we can customize it as long as we understand the necessary parameters, your products, etc. In order to ensure that the equipment meets the requirements, we can make samples free of charge.

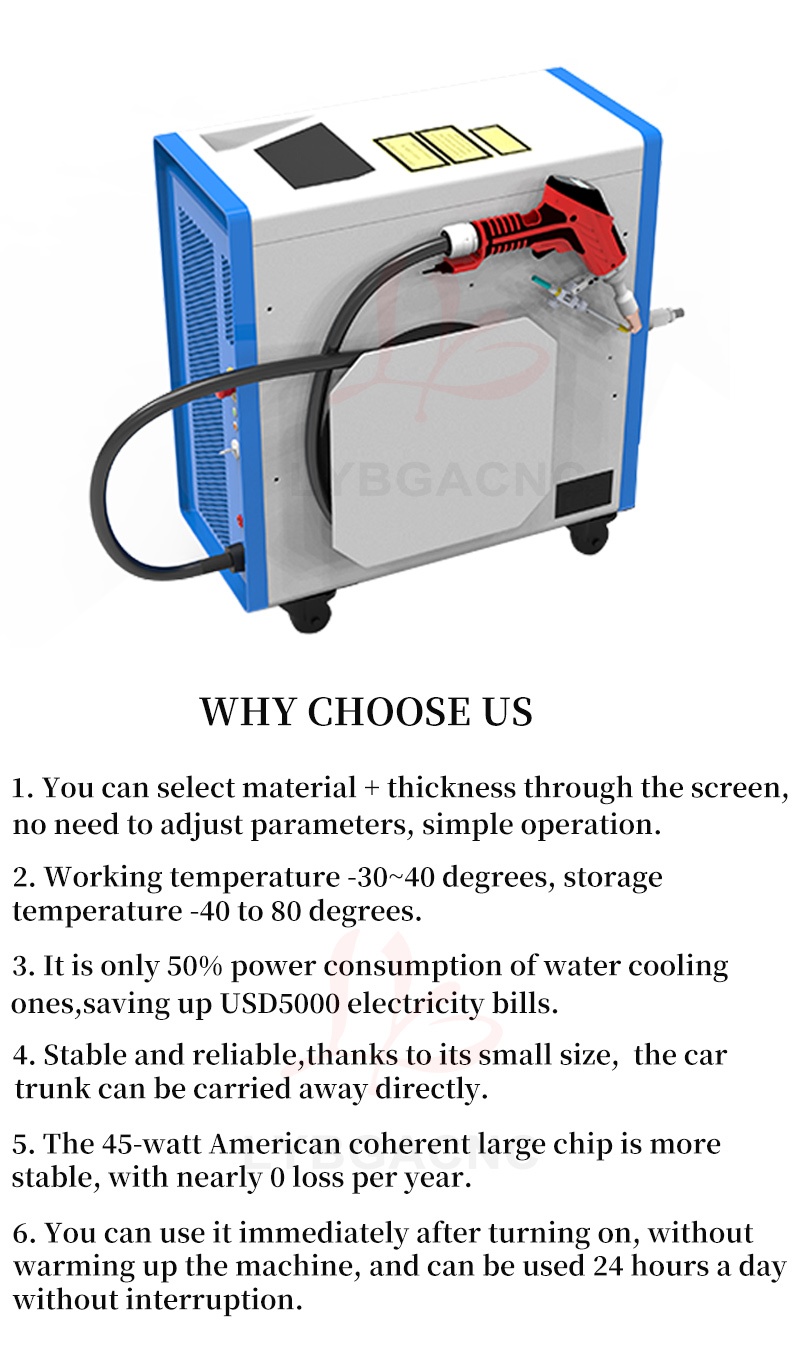

WHY CHOOSE US

1. You can select material + thickness through the screen, no need to adjust parameters, simple operation.

2. Working temperature -30-40 degrees, storage temperature -40 to 80 degrees.

3. It is only 50% power consumption of water cooling ones, saving up USD5000 electricity bills.

4. Stable and reliable, thanks to its small size, the car trunk can be carried away directly.

5. The 45-watt American coherent large chip is more stable, with nearly 0 loss per year.

6. You can use it immediately after turning on, without warming up the machine, and can be used 24 hours a day without interruption.

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!