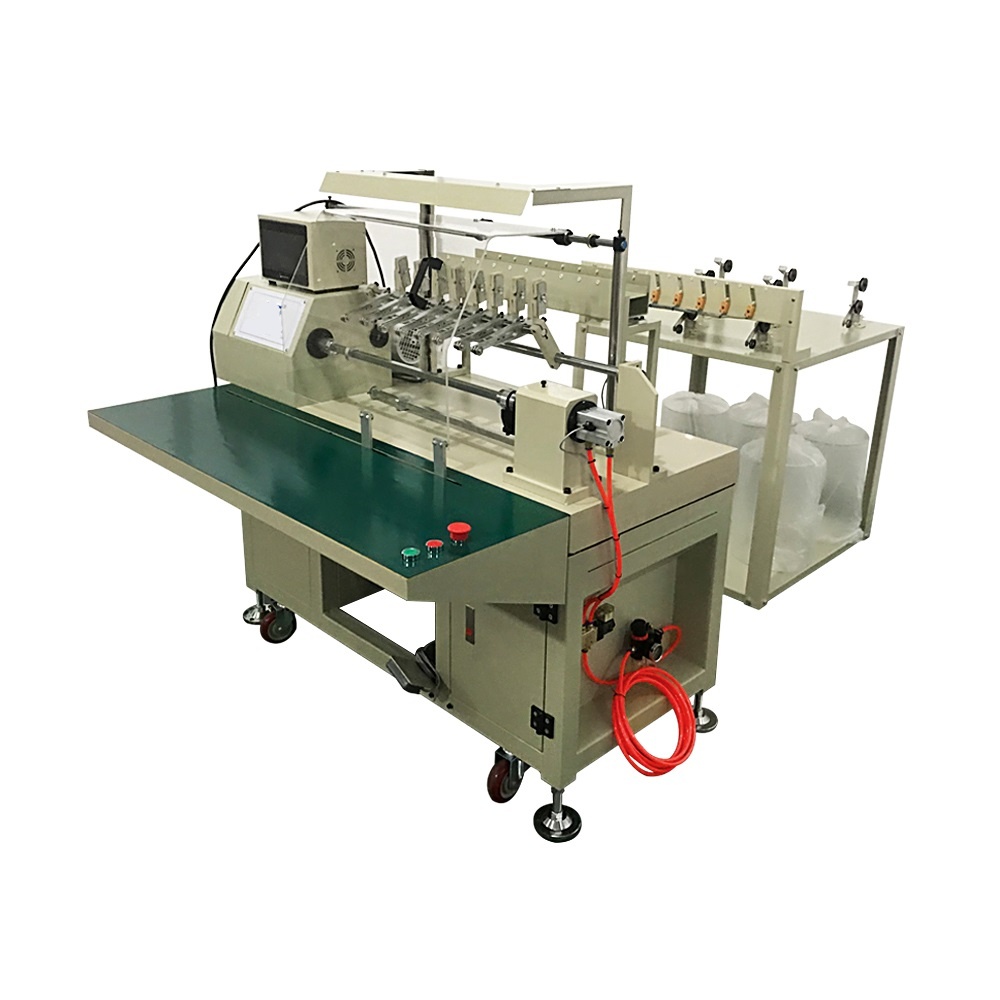

Industrial LY 880 Eight Heads Motors Stator Coil Winding Machine 750W Spindle Total Power 900W OEM Accepted First Hand Factory Supply

Product Detail

Product Tags

Industrial LY 880 Eight Heads Motors Stator Coil Winding Machine 750W Spindle Total Power 900W OEM Accepted First Hand Factory Supply

Features:

◆ 32-bit arm control chip, CPLD, more faster operation speed, obvious effect to reduce the error of line arrangement.

◆ all the input and output are photoelectric isolated and stable.

◆ all English LCD, easy to operate.

◆ intelligent input of winding starting and line width.

◆ intelligent deceleration of line reversing ensures that there is more torque while fast line arrangement.

◆ it can set the time of spindle climb, change the speed of spindle in real time and track the overspeed.

◆ power off to save winding data, effectively avoid coil scrap caused by sudden power failure.

◆ adopt the bearing belt imported from Japan, imported screw rod from Taiwan, and integral iron spindle box

The body ensures stable performance.

Parameters:

| Spindle quantity | 1 |

| Working station | 8 |

| Spindle speed | High speed 0-3200rpm ,Low speed 0-1600rpm |

| Applicable line diameter | 0.05-0.8mm |

| Rotating diameter | 0-160mm |

| Line travel | 0-180mm |

| Line speed | 0-33mm/ s |

| Spindle motor | 750W three-phase AC motor w +750w frequency converter ((large wire diameter is more |

| The wire head is equipped with high-power motor as required) | |

| Two phase hybrid stepping motor with static torque of 2n.m | |

| Single phase power supply | 220V ±% 10% 50HZ |

| Total power | 900W |

| Machine size | length 1350mm x width 850mm x height 1200mm |

| Machine weight | 400kg |

Frequency converter made in china

Spindle motor made in china

Domestic line motor, 2n.m static torque, long-term working without heating

The controller is independently developed, 32-bit arm control chip, all English touch screen LCD

Display, can be one key to generate all steps, parameter settings are simple.

TBI, C-level precision of screw rod Taiwan

V-belt, Osaka, Japan

Bearing Japan NSK

Main shaft line box cast iron box, independently developed

Working table cast iron platform, independently developed

Independent R & D of other mechanical parts

Software

◆ basic parameters input of skeleton. Starting point, line width, spacing, winding ring

Number: start idle, stop idle, positioning of main shaft, low speed of main shaft, high speed of spindle,

Spindle direction, line arrangement direction, layer stop.

◆ setting of the climbing time of the spindle and selection of special winding function.

◆ the system has 1450 data storage space, and can save up to 999 skeleton parameters

Number. The adjusted skeleton parameters can be saved permanently. When replacing products, only need to be replaced

The corresponding fixture, select the corresponding skeleton parameters.

◆ when winding, the system will suddenly lose power, and the system will keep the final winding state. After power on again,

Press the start key to continue winding the unfinished coil.

Special functions can be customized software.

● Packing:

◆ package size: length: 1480mm wide: 1180mm high: 1520mm

◆ gross weight: 460Kg

Scope of application

◆ various motor coils

Small motor

◆ washing machine motor

◆ fan motor

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!