Tapping Machine Vertical Type Universal Electric Tapper Threading Machine M6-M24-M36

Product Detail

Product Tags

Tapping Machine Vertical Type Universal Electric Tapper Threading Machine M6-M24-M36

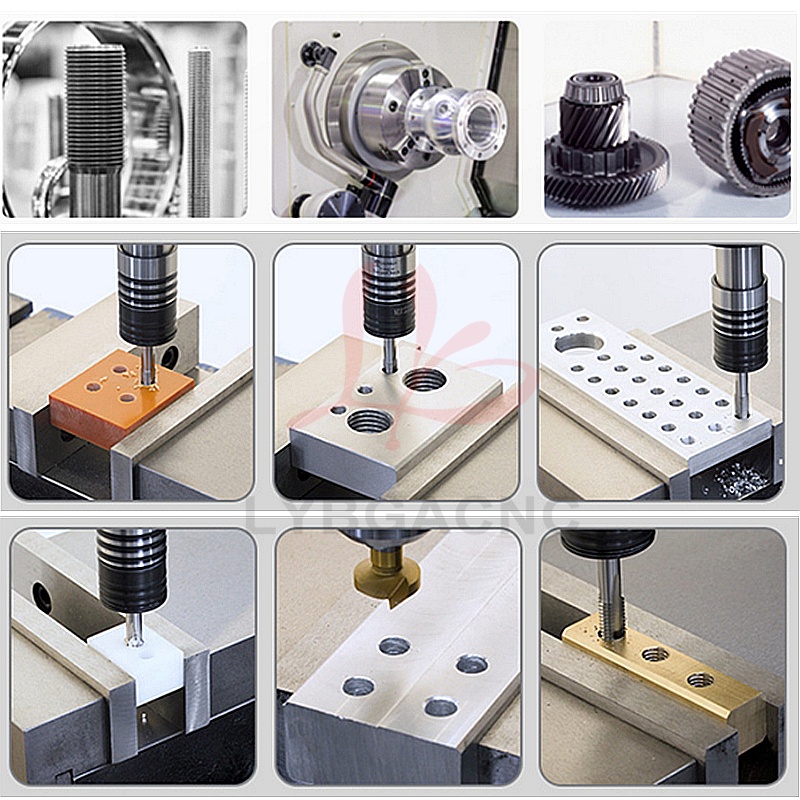

Electric tapping machine is applicable to all machinery manufacturing industry, machine tool, mould machinery, plastic machinery, printing machinery, packaging machinery manufacturers, engineering machinery, automobile motorcycle parts, aviation engines, rolling stock, tobacco machinery and general machinery and other industries.

Electric tapping machine for workpiece materials: electric tapping machine can be in the lead, copper, A3 steel, cast iron, cast iron, Q235, 45#steel, S136 steel, 718 steel, ace, NAK80 die steel and other metal materials for easy tapping operations.

Machine features:

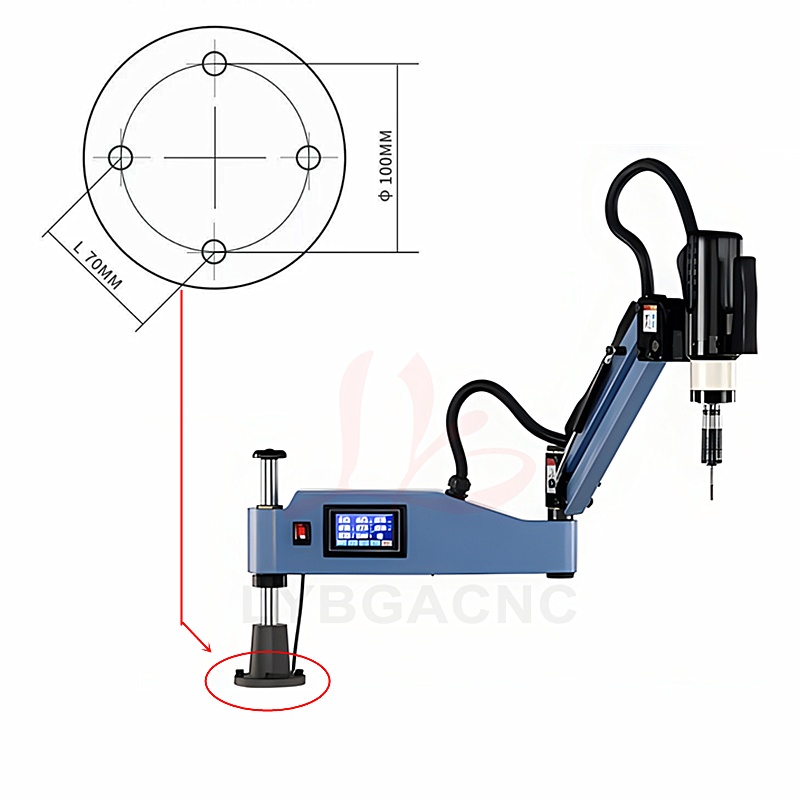

1.The tapping motor of the tapping machine is balanced and perpendicular to the suspension support frame, which can keep the tapping motor moving to any position and can be kept perpendicular to the workbench.

2.The tap of the tapping machine is equipped with overload protection device. With the clamping head of overload protection device, the safety clutch can be adjusted when the tapping exceeds the rated torque, and can avoid damage to the tap.

The machine can be used in single-phase 220V power supply.

3. It has the advantage of high cost performance, lower price and more function than the domestic and international model machines, and many inventions surpass other brands.

4. Advanced mechanical design, all kinds of processes are used in moulding production, with low cost and beautiful appearance.

5. Simple and flexible operation, able to quickly locate and accurately process complicated and bulky work.

6. Can (optional) universal head, the work head can adjust at any Angle, vertical, horizontal, lateral, high and low can tap the silk.

7. The taper sleeve has an overload protection device to ensure that it does not damage the tap, the load balance in the tapping process, the high precision of the screw processing, and the protection of the torsion force.

8. Infinitely variable speed, can adjust any speed, the speed can be set on the controller.

9.manual, automatic and gap three modes of work are your choice.

10.Automatic mode can control the tapping depth effectively, without operation button, it is controlled automatically by the depth controller.

11. Rapid positioning, quick tapping speed and high production efficiency.

12.Servo drive control, overcome the limitations of pneumatic tapping machine, lathe, drilling machine or manual tapping machine.

Details:

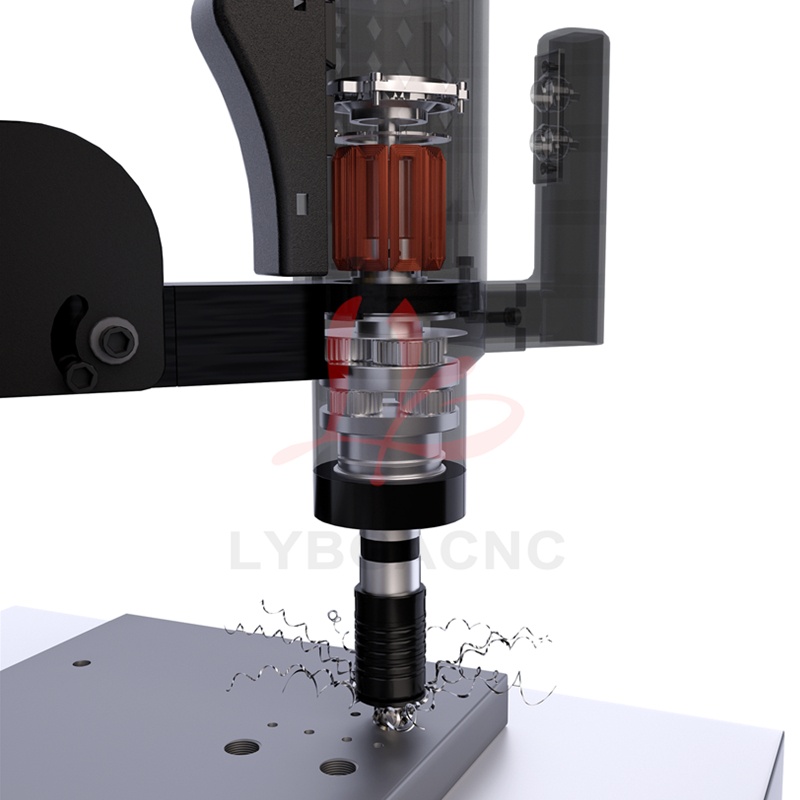

1.Equipped with high speed servo motor, the maximum speed can reach 5000 revolutions per minute. Stable performance and long life.

2.Super wear-resistant planetary reducer, stable performance, low noise. Average life is 20000 hours, noise is less than 60DB. Lubrication: long acting grease. Protection level: 1P65.

3.The right handle handle design, can use the thumb to control the speed switch (ergonomic design), flexible, smooth.

4.Detachable handle on the left, hands operating on the head, positioning is more flexible, accurate and fast.

5.Tapping machine chuck, (switching clip).

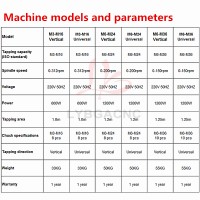

Parameters:

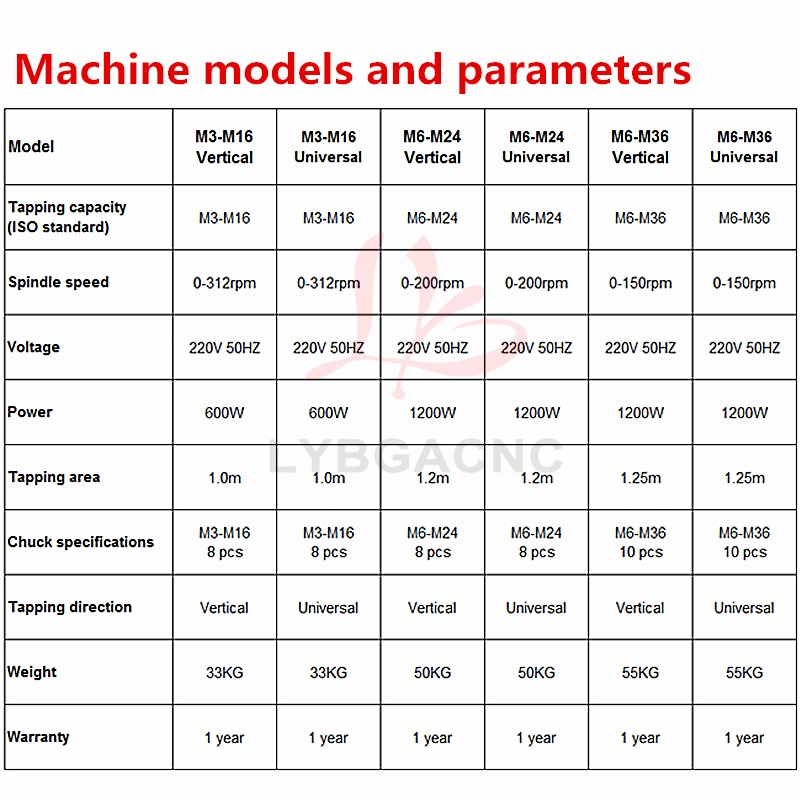

Model: M6-M24

Voltage: 220V

Motor Power: 1200W

Electric current: 50HZ/60HZ

Spindle speed: 0-200/RPM

Working radius: 1200mm

Working angle: Vertical & Universal type

Chuck type: M6/8 M10 M12 M14 M16 M18/20 M22 M24

Control panel: Touch screen

Tap capacity: M6-M24

Packing size: 65CM*61CM*22CM

Weight: 50kg

Model: M6-M36

Voltage: 220V

Motor Power: 1200W

Electric current: 50HZ/60HZ

Spindle speed: 0-156/RPM

Working radius: 1200mm

Working angle: Vertical & Universal type

Chuck type: M6/8 M10 M12 M14 M16 M18/20 M22 M24 M27/30 M33 M36

Control panel: Touch screen

Tap capacity: M6-M36

Packing size: 65CM*61CM*22CM

Weight: 50kg

Warm Tips:

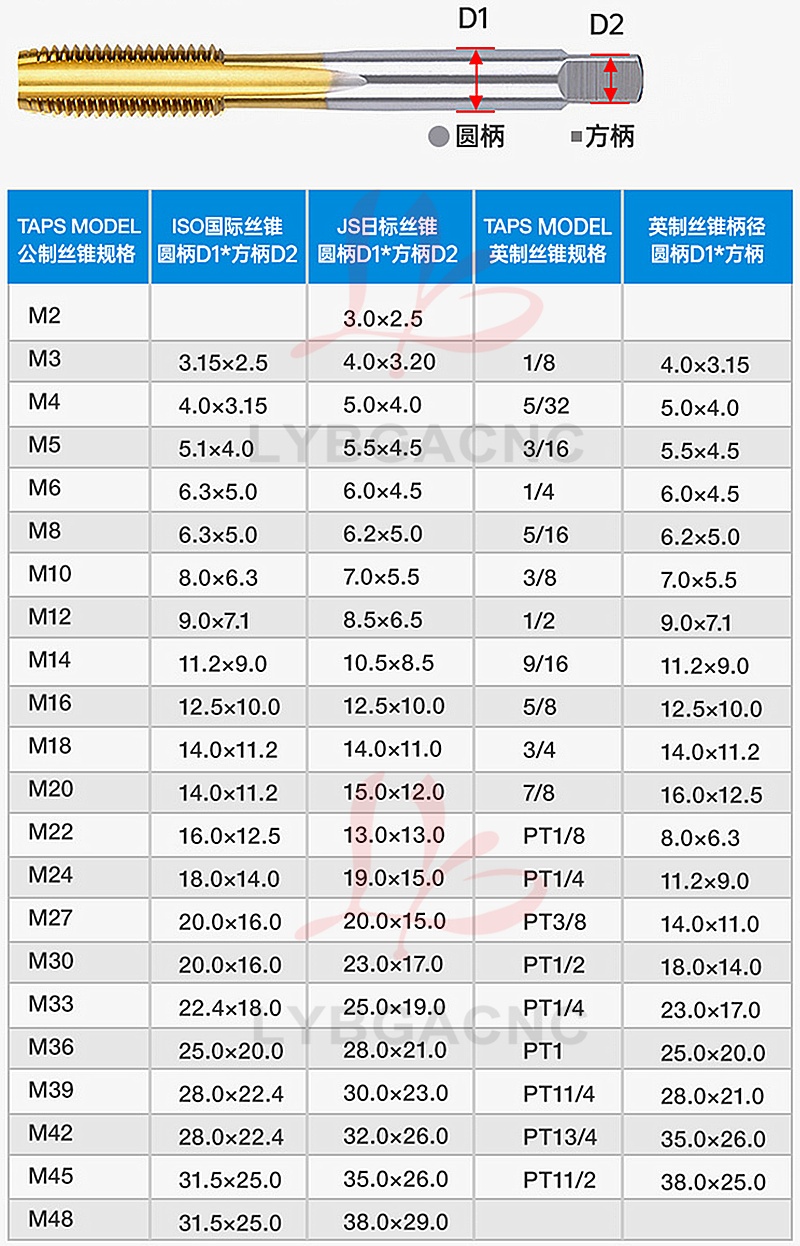

- The Chuck standard ISO Chuck, If You need JIS or DIN, please message us;

- The tapping machine does not contain bottom mounting table

Because mounting table is made of cast iron, very heavy, freight is very expensive,

so we suggest that customer can make it by themself or buy it in local

Thank you very much!

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!